Nuclear Energy Activist Toolkit #26

NEAT #25 described regulatory requirements that seek to ensure that nuclear safety levels are not diminished by modifications to the plants or by revisions to procedures used by plant workers. This post covers complementary requirements that modifications and maintenance achieve proper outcomes.

Appendix B to 10 CFR Part 50 contains 18 quality assurance criteria. Criterion XI requires initial and periodic demonstrations that structures, systems, and components can perform necessary safety functions. Criterion XVI requires that non-conforming structures, systems, and components be promptly identified and corrected. If new equipment is installed, old equipment is replaced, or existing equipment is repaired, testing must be performed afterwards per these regulatory requirements to show the equipment is fully functional. The testing protects against installing wrong parts, installing the right parts improperly, and other problems that can undermine safety levels.

An Example

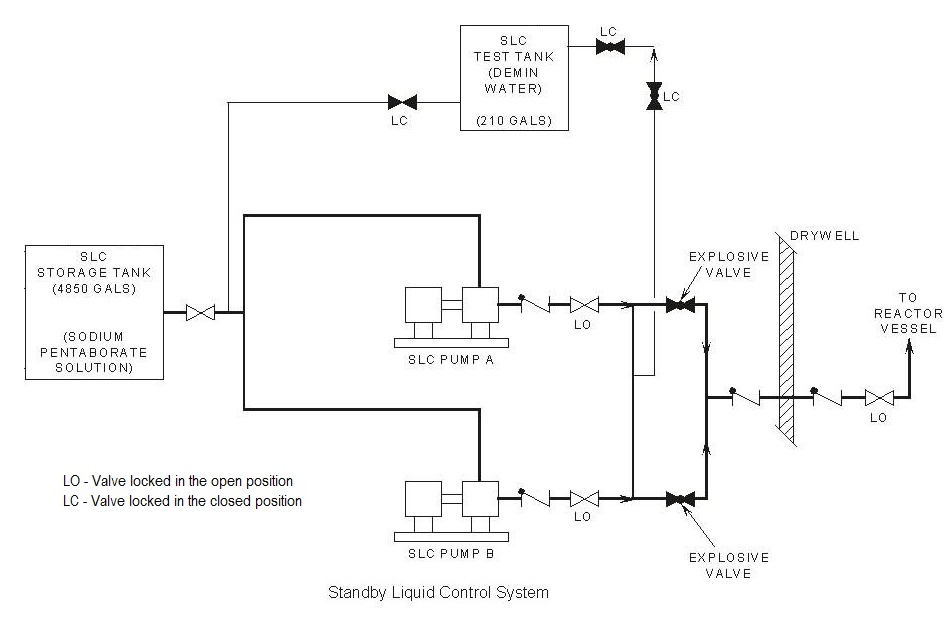

Consider the example involving the replacement of the electric motor for one of two pumps in the standby liquid control (SLC) system on a boiling water reactor. The SLC system is a backup to the control rod system normally used to stop the nuclear chain reaction in the reactor core during an accident. If the control rod drive system fails, the operators in the control room can turn a switch to automatically start one of the SLC pumps (the second is a backup in case the first pump fails). The pump transfers sodium pentaborate solution (containing boron, the same material used in control rods to stop the chain reaction) from a storage tank into the reactor vessel.

NRC’s regulations require that the SLC pump with the new motor be tested to verify its performance. To allow testing but not have it result in sodium pentaborate solution reaching the reactor vessel, the SLC system is equipped with a smaller tank. Workers re-position normally closed and opened valves to allow a pump to be started. In this testing configuration, the running pump draws water from the SLC test tank and returns it to that tank in a closed loop. This configuration allows post-maintenance testing of the SLC pump to be performed to verify that a replacement motor is functioning properly.

It is common to test a safety system in such a segmented manner; test the pumps, then test the control circuit that starts the pumps, and finally test the explosive valves that must open to allow the pumps to deliver solution to the reactor vessel. But sometimes, successfully testing A to B, then B to C and then C to D does not ensure that A to D can be reached.

In January 1996, the NRC required plant owners to review their testing procedures to verify that segmented tests reflect overall system performance. In other words, to ensure the results from segmented tests would be the same from an integrated test of the entire system.

Bottom Line

Seldom a month passes without an NRC inspector finding or a plant owner reporting a safety problem that had existed for years. For example, in January 2014, the owner of the McGuire nuclear plant in North Carolina informed the NRC about a design flaw in a power supply for the control rods in the Unit 1 reactor . This flawed power supply remained undetected for 16 years until it caused the unplanned shut down of the reactor from full power.

Why didn’t the post-installation testing find this design flaw back in 1997?

Why doesn’t the NRC ask the owner why it violated regulatory requirements for post-installation and post-maintenance testing.

Why doesn’t the Congress ask the NRC why it has federal safety regulations if it’s not going to enforce them?

The UCS Nuclear Energy Activist Toolkit (NEAT) is a series of post intended to help citizens understand nuclear technology and the Nuclear Regulatory Commission’s processes for overseeing nuclear plant safety.