Electric transportation is essential for a cleaner and healthier world. Replacing gasoline vehicles with electric can reduce emissions that cause climate change and illnesses. Researchers like me are putting a microscope to the electric vehicles (EVs) because, as with any extraction and manufacturing, there are associated impacts. We are specifically looking at the social and environmental impacts of mining and processing the minerals that are used in the batteries powering these vehicles, buses, bikes, and scooters.

The research we’re pursuing about EV batteries is not a call to halt progress and remain mired in the gasoline-powered status quo. To the contrary, it’s a call to ensure that the necessary transition away from gasoline creates the most equitable and sustainable future possible.

While this may seem obvious, some news coverage on EV mineral impacts have not accurately portrayed this motivation. In many cases the problems associated with EV materials are posed as attention-grabbing headlines and the focal point of the issue, rather than focusing on the solutions to more sustainable electrified transportation. A human rights researcher and journalist, Mark Dummett, raises a similar concern, stating that this information is being used by some bad actors for self-serving purposes.

So how, with this muddled messaging, can the public understand the underlying issues and potential solutions to creating a low impact transportation system? Well, let me try to provide a full picture.

Let’s talk solutions

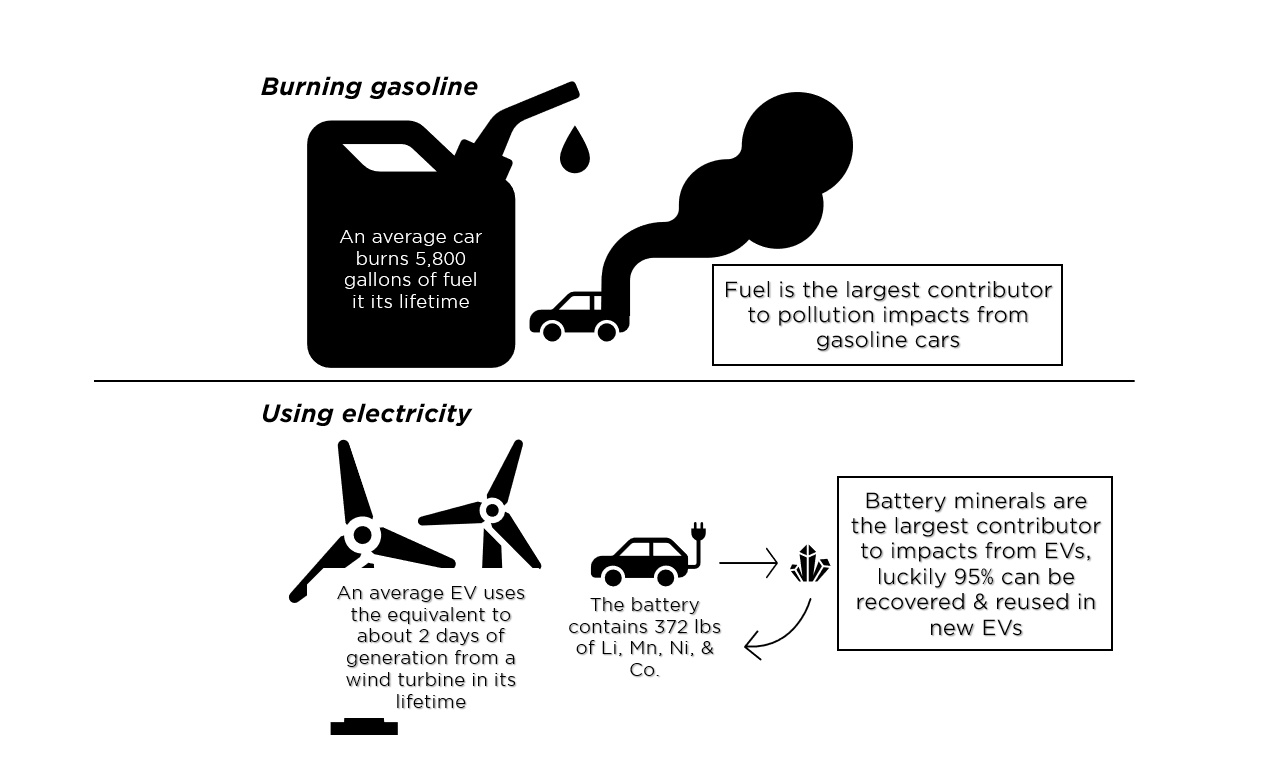

A solution to decreasing pollution is moving away from gasoline-based modes of transportation to electric. The oil-based status quo today is unsustainable. Gasoline and diesel have a myriad of environmental and social impacts, but the largest pollution impacts come from the extraction, refining, and burning of petroleum required to power the vehicle.

EVs powered by today’s electricity grid produce significantly less carbon emissions than gasoline cars and can be powered by renewable energy. Batteries for EVs require more minerals than gasoline cars. However, unlike burning petroleum, where once petroleum is burned the resource is depleted, batteries can be recycled at high recovery rates when EVs are retired and used to make new batteries, reducing the need for newly- mined materials over time.

While the benefits in comparison to a gasoline vehicle are clear, there are still environmental and social impacts associated with EV battery mineral mining and processing. In this transition, there is a huge opportunity to create a sustainable, equitable, and circular transportation system.

EVs can take us to a cleaner future – but we need to steer them to get there

Several steps are necessary to create a sustainable and ethical electrified transportation system.

First, we need to ensure that equitable practices are in place to reduce mining impacts.

Various approaches are outlined by several organizations, including the United Nations, OECD, and the Initiative for Responsible Mining Assurance. The European Union has recently agreed on legislation requiring these frameworks, therefore taking steps for due diligence in their battery supply chain.

Next, we need a basket of solutions to efficiently use the materials we extract.

Strategies like increasing transit, building out infrastructure for walking and biking, choosing more efficient vehicles, ensuring access to convenient and affordable charging, and reusing and recycling batteries can all contribute to reducing demand for EV battery materials.

I’ve discussed the potential for battery recycling to reduce overall material demand in previously blogs, but there is also huge potential for several of these other strategies to reduce future mineral demand from the transportation system.

Let’s take a closer look at some of the various solutions to efficient use of materials.

Increasing public transportation and the walkability and bikeability of a city can reduce the number of EVs needed and therefore the amount of battery minerals necessary to meet mobility needs.

Buses are a more efficient use of battery materials since an effective bus system can transport many more people per trip. Studies in Denmark and Spain have demonstrated that increased public transportation in urban areas could help reduce the need for car ownership. This reduced car ownership can directly reduce the amount of minerals needed to support an electrified transportation system. A recent study the potential for reducing up to 66% of projected lithium demand in 2050 compared to business as usual if US cities moved aggressively toward multimodal transportation systems.

Improving efficiency of vehicles can reduce the amount of minerals needed to electrify our vehicle fleet and the associated impacts.

Just like more efficient gasoline vehicles mean you can go further on a tank of gas, more efficient EVs means going further on a full charge. In turn, that means you can use a smaller-sized battery to get where you need to go.

Take the F150 Lightning for example. Pick-up trucks are larger, heavier and less energy efficient than cars, so they need a larger battery to travel the same distance. The F150 has a 113 kWh battery (98 kWh useable capacity) and a vehicle efficiency of .49 kWh per mile – so it can travel about 230 miles on a full charge. The Tesla Model 3 on the other hand, has a 70 kWh battery (65 kWh useable capacity), efficiency of .26 kwh per mile, and can travel 272 miles on a full charge. If you are hauling materials or towing, the F-150 may be the right choice, but for moving up to five people 200+ miles, the Tesla can achieve that with less electricity use and a smaller battery. Automakers can up their game by making vehicles as efficient as possible and offering a wide-range of electric models including smaller cars and consumers can help by choosing the most efficient EV that meets their needs.

Even an efficient EV can have a large battery. Automakers use vehicle range as a selling point to consumers, but buyers should beware. Larger batteries not only increase the cost of an EV but add to the demand for battery materials – and you may not need that larger battery. Most EVs on the market today have about a 250-mile range on a full charge – but some automakers are offering models with 300, 400, or 500+ mile range. These higher range models mean you are not only paying a lot more – but lugging around a larger battery and likely only using a small portion of it. Understanding your driving habits and charging options at home, work, and elsewhere can also give you more confidence that extra battery capacity might not be needed. Automakers and charging providers can help by ensuring easily accessible, affordable, and reliable public fast charging to give consumer the confidence that they will have charging when they need it.

Just to put this in perspective, the US sells about 15 million new vehicles per year. If those were all EVs with a similar efficiency, battery size, and chemistry to the 2022 Tesla Model 3, they would require 107,000 metric tons of lithium. If they were all equivalent to the battery size, efficiency, and chemistry to the 2022 F150 Lightning, they would require 170,000 metric tons – 58% more. So, making sure EVs are efficient can avoid the unnecessary use of a lot of materials.

Recovering minerals through recycling to then manufacture new batteries can reduce the need for new extraction and mining.

Recycling batteries at their end of life reduces demand for mining and the creation of a lower impact and local mineral supply chain. Recovering materials through recycling old batteries has a much lower environmental impact than sourcing minerals through mining, plus retired batteries have the potential to supply a significant amount of recycled materials. My research demonstrates that recovered minerals in the US can supply about 49% of cobalt, 43% of nickel, and 25% of lithium demand for EVs in 2050. Other research demonstrates even high circularity potential with recovered lithium can meet up to 49% in 2050 if multimodal transportation options also expand, therefore decreasing the amount of EVs purchased and the overall minerals needed.

Electrify our transportation system through smart, ethical, and equitable action

It’s essential that we implement the many solutions provided by researchers and affected communities and not repeat the past mistakes of the fossil fuel industry. As we phase out petroleum, we have an opportunity to create a more efficient transportation and manufacturing system. We can reduce the impacts associated with battery technology for a more clean, ethical, and equitable electrified transportation system.