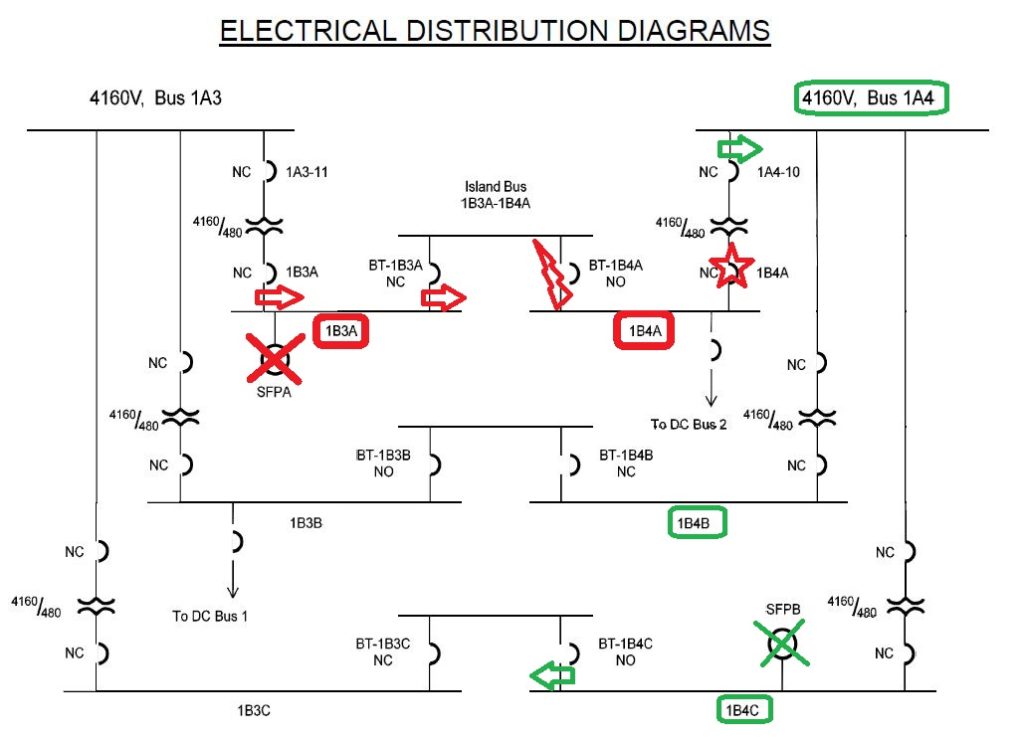

At 9:27 am on June 7, 2011, 480-volt electrical breaker 1B4A (marked with a red star in the figure) catastrophically failed at the Fort Calhoun nuclear plant near Omaha, Nebraska. The ensuing chain of events shut down cooling to the spent fuel pool.

The breaker’s failure started a fire. Smoke and soot from the fire allowed electricity to arc across an open electrical breaker (BT-1B4A, marked with the red spark in the figure) to cause voltage fluctuations on the 480-volt electrical buses connected to it (“island bus”1B3A-1B4A and 1B3A in the red square).

An electrical bus is like a string of Christmas tree lights. Unplugging one string causes all its lights to go out, but lights in other strings still plugged in remain lit. If one string is directly connected to another string, then all the lights can go out.

The electrical transients in these buses caused breakers 1B3A and BT-1B3A (red arrows in figure) to automatically open to isolate the problem and prevent it from cascading throughout the plant. The opening of these two breakers de-energized 480-volt electrical bus 1B3A, which in turn cut the power supply to spent fuel pool cooling pump A (labeled SFPA in the figure – at the red X). Spent fuel pool cooling pump A had been running at the time to cool the irradiated fuel stored in the spent fuel pool.

The failure of breaker 1B4A prevented it from opening, either automatically or in response to efforts by the operators in the control room. Instead, the operators manually opened breaker 1A4-10 (green arrow at top right of the figure) to stop electricity flowing from 4,160-volt bus 1A4 to the damaged breaker. Per procedure, the operators then cut electrical power to 4,160-volt bus 1A4. This also cut power to 480-volt buses 1B4B and 1B4C (green squares in figure).

Since the second spent fuel pool cooling pump – B (SFPB) – was supplied from bus 1B4C, it also shut down (green X in the figure). The fire had now shut down both spent fuel pool cooling pumps, and they would remain unavailable for nearly 90 minutes.

The fire was reported out at 10:19 am. It had burned for less than an hour.

The operators closed breaker BT-1B4C (green arrow at bottom of figure) at around 11:45 am. This enabled electricity from 4,160-volt bus 1A3 to flow through 480-volt bus 1B3C and re-energize 480-volt bus 1B4C. The operators then started spent fuel pool cooling pump B. The spent fuel pool’s water temperature rose 3°F during the 90 minutes that cooling was lost (Calhoun had been shut down for nearly two months for a scheduled refueling outage at the time of the fire).

The NRC sent a special inspection team to Fort Calhoun. The NRC team reported that there had been ample signs of trouble before the fire, but that reactor operators had failed to act on them to avoid the problem. Workers noticed an “acrid odor” in the small room housing electrical breaker 1B4A and 480-volt bus 1B4A three days before the fire. Had it been a school, theater, office, or any place other than a nuclear plant, the individuals would have said they smelled smoke. “Acrid odor” is nukespeak for “smoke” (as in “No telling what that dude was acrid-odoring”).

The NRC team learned that workers again noticed an acrid odor in the room the day before the fire and entered a report in the plant’s corrective action program about it. But even though the plant had instruments onsite to perform thermographic scans of the electrical equipment to identify hot spots that might be sources of the acrid odor, they were not used. Workers also failed to employ low-tech preventive methods like opening electrical panels to look for smoke and check for abnormally high temperatures.

In short, they failed to heed the nuclear adage “Where there’s acrid odor, there’s rapid oxidation.”

The electrical breaker that failed was among 12 breakers replaced in November 2009. The replacement breakers were of a different size and material than the original breakers. These design differences caused the breakers to experience higher temperatures during operation due to increased resistance to electrical current flow. The higher temperature only exacerbated the situation by increasing the rusting rate of internal metal parts, adding even more resistance to current flow.

During installation, the replacement breakers did not align properly to bus connections within the breaker compartments. Workers made unapproved, on-the-spot changes to make them fit. Following installation, workers used a hand-held mirror to see if the pieces seemed to fit together properly. They did not measure the incoming and outgoing electricity to confirm consistency with the performance characteristics of the original breakers.

Following replacement of the breakers, workers periodically cleaned the breakers. But they only cleaned part of the connection between the breakers and their buses. They did not remove hardened grease that was present on other connecting parts. This grease increased the electric current resistance which further elevated the temperature of the breakers during operation.

The NRC inspection team identified a deficiency in the plant’s fire protection design. Specifically, the plant’s design was supposed to prevent a fire or electrical transient from propagating from one safety train to another safety train. The 4,160-volt buses 1A3 and 1A4 are in different safety trains, yet a fire affecting 480-volt bus 1B4A crossed isolation boundaries to impair 480-volt bus 1B3A in the other safety train.

Consequently, a single fire de-energized both spent fuel pool cooling pumps. These pumps had been powered from different safety trains to prevent such an outcome.

The NRC team also identified several problems with workers’ response to the fire including:

- After breaker 1B3A unexpectedly opened and de-energized the only running spent fuel pool cooling pump, the operators made repeated attempts to re-close it from the control room. But the design of this electrical breaker required that it be reset locally after opening locally, a fact that the operators had not understood from their training and operating procedures.

- Contrary to procedures, the onsite fire brigade leader relinquished command to the offsite fire department when it arrived. Onsite command is required because offsite responders are not trained on the plant’s systems and may not understand the adverse consequences from de-energized or disabling equipment during their firefighting efforts.

- No one searched the fire area for potential victims nor was an accountability check performed to verify that no workers were missing.

The NRC issued a Red finding, the most serious of its four color-coded severity classifications, for three violations that set the stage for this fire to happen and enable it to have larger consequences than necessary.

Our Takeaway

The NRC has only issued a handful of Red findings over the 12 years that its Reactor Oversight Process has been in place. Fort Calhoun earned this relatively rare dishonor from violations that increased both the probability and consequences of a fire. One of the adverse consequences from the fire at Fort Calhoun was loss of spent fuel pool cooling.

Spent fuel pool and fire protection hazards are the top two safety concerns monitored by UCS with our Nuclear Power Information Tracker. It shows that:

- 33 reactors store irradiated fuel in elevated spent fuel pools, like at Fukushima.

- 47 reactors do comply with NRC’s fire protection regulations.

- 10 reactors storing irradiated fuel in elevated spent fuel pools also do not meet fire protection regulations.

Fort Calhoun’s luck ran out and it had a fire that exposed its vulnerabilities.

If any of the reactors with known safety shortcomings has its luck run out, the NRC should have some explaining to do. Right after the NRC issues its Red finding to the unlucky owner.

But someone should issue a Red finding to the NRC for continuing to tolerate safety problems as bad as – or worse than – Fort Calhoun’s. Or at least make them get a gaming license for the nuclear lottery they’re running.

“Fission Stories” is a weekly feature by Dave Lochbaum. For more information on nuclear power safety, see the nuclear safety section of UCS’s website and our interactive map, the Nuclear Power Information Tracker.