The defense-in-depth approach to nuclear power safety employs multiple barriers between radioactive materials and the environment. While no single barrier is 100 percent reliable, multiple barriers reduce the chances that all fail to prevent radioactive materials from reaching the environment.

One such barrier is the hollow metal rods containing fuel pellets inside the reactor core of a nuclear power plant. These fuel rods, when intact, prevent the radioactive particles and gases formed as a byproduct of fissioning atoms from escaping into the reactor cooling water.

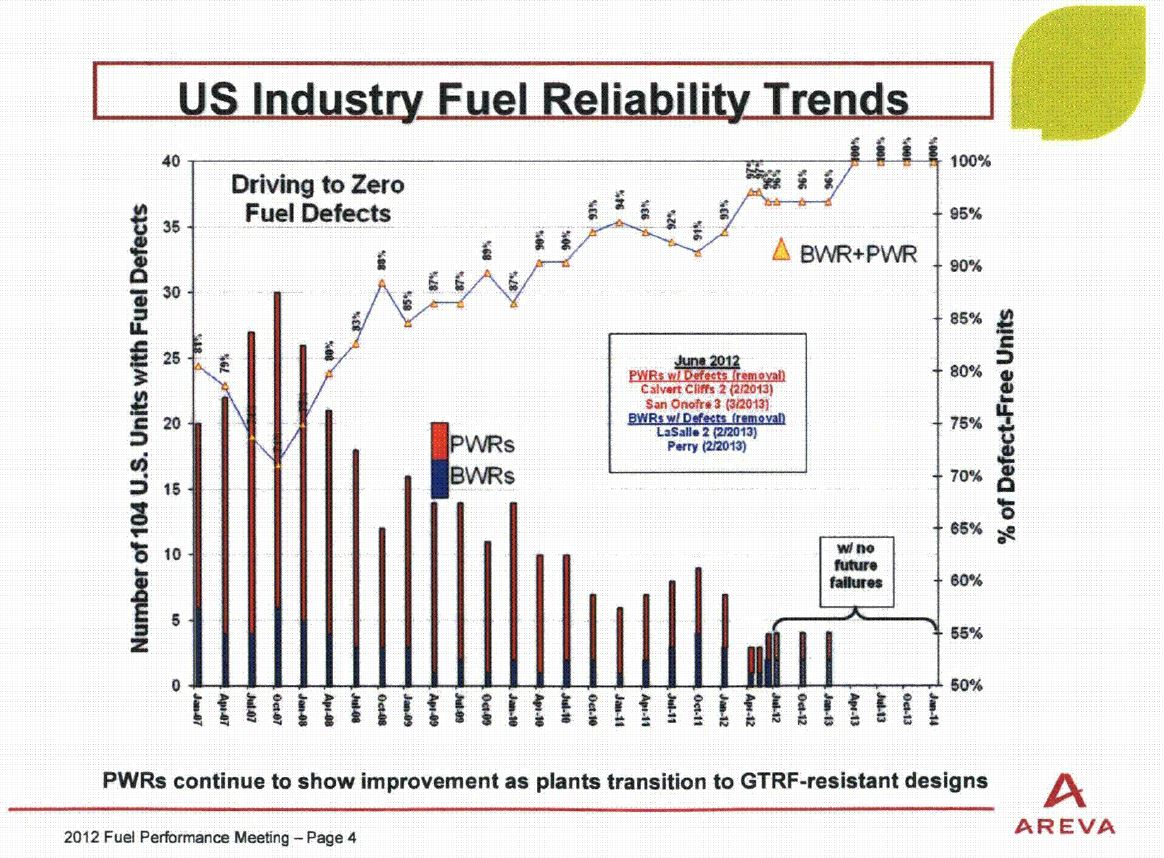

The good news is that fewer nuclear power plants are operating with defective fuel rods (see Figure 1). Where 20 to 30 percent of the plants had defective fuel rods just five years ago, fewer than 5 percent operated with fuel defects last year.

This trend is certainly good news. Fewer defective fuel rods put less radioactive particles and gases into the reactor cooling water. Less contaminated water means lower radiation doses to workers performing maintenance and testing on plant equipment. And more of the radioactive particles and gases being retained in the fuel rods mean less being discharged to the air and water.

But there was bad news associated with this good news. The owner of the Oconee nuclear plant in South Carolina informed the NRC that the improved fuel rod reliability had a safety side effect. The plant’s operating license contained a requirement that a leak of one gallon per minute of reactor cooling water into containment be detected within an hour. This requirement stemmed from the leak-before-break concept: a pending rupture of a large pipe connected to the reactor vessel would be preceded by a small leak. The plant’s operating license also contained a complementary requirement that the reactor be promptly shut down if a small leak was identified.

There are many tanks and pipes containing water inside containment. For example, there are large tanks of borated water standing ready to inject this volume into the reactor vessel in event a pipe breaks and drains cooling water. And there are air conditioning units inside containment supplied with cooling water.

To differentiate between a puddle on the containment floor caused from a leaking a borated water tank or from the cooling water supply pipe to an air conditioner, the instrument used to monitor the reactor cooling water leak rate relied on the fact that this water would be radioactively contaminated. In other words, the monitoring instrument was not tracking drops of water as much as it tracked the amount of radioactivity that would be within the reactor cooling water.

But improving fuel reliability meant less amount of radioactivity in the reactor cooling water. The instrument was not re-calibrated to retain its ability to detect a one gallon per minute leak rate within one hour. It would either require a larger leak rate (e.g., 10 gallons per minute) or a longer time period (e.g., 4 hours) for the instrument to indicate a problem.

Workers at Oconee re-calibrated the instrument to restore the required sensitivity and revised procedures to use the amount of radioactivity actually present in the reactor cooling water in future calibrations.

Our Takeaway

No one could possibly have anticipated that improving fuel reliability would have adverse implications on the ability to detect leaks of reactor cooling water inside containment.

Unless of course one read the August 3, 2005 warning issued by the NRC on this very matter.

In that warning, the NRC cautioned owners that fuel reliability improvements had reduced the amount of radioactivity within the reactor cooling water with the result that instruments used to detect leakage inside containment “may not be able to detect a 1 gallon-per-minute (1-gpm) leak within 1 hour.”

The NRC based this warning on information it received May 2, 2005 from the owner of the McGuire nuclear plant. That owner informed the NRC it became aware on December 19, 2004, of industry operating experience about other nuclear plant in the US having problems detecting reactor coolant system leakage inside containment and took corrective actions at McGuire after determining it shared the problem.

But the owner of the McGuire nuclear plant also owns the Oconee nuclear plant. Why did it take 8 more years for workers at Oconee to learn (and fix) what workers at McGuire leaned?

More importantly, why does the NRC put up with this nonsense?

The NRC warned Oconee’s owner – in writing – back in August 2005 about a safety problem detected at one of this owner’s other nuclear plants. But the owner essentially ignored both the NRC’s warning and the lessons learnable from McGuire to let the three reactors at Oconee operate for 8 more years with the same problem.

The NRC’s 2005 warning, in theory, should take away this owner’s “get out of jail free” card. The NRC warned the owner, in writing, about this problem. The owner cannot claim ignorance about it in 2013.

But it would do little good for the NRC to throw the book at this owner for violating this safety requirement. If this owner cannot be bothered to read the NRC’s three page warning letter, it likely won’t read the book whizzing by either. Maybe the NRC should consider doing more to get this owner’s attention – like causing the plant to be shut down for awhile as the agency has been doing at Fort Calhoun in Nebraska. Now that the NRC has that owner’s attention, all kinds of longstanding safety problems are now being found and fixed. Oconee’s owner seems to be begging the NRC for this same kind of healing treatment.

NRC – heal that wayward owner before it’s too late.

“Fission Stories” is a weekly feature by Dave Lochbaum. For more information on nuclear power safety, see the nuclear safety section of UCS’s website and our interactive map, the Nuclear Power Information Tracker.