A global transition to electric transportation is underway and momentum is growing. Traditional and new auto manufacturers are bringing more and more models to market. Even in California, where a tradition of stringent regulation has pushed the industry to innovate over the past 50 years, automakers are selling EVs at levels well above sales requirements. This momentum is spreading across the country with US EV sales now over 9% and climbing.

When a change as big as this is underway, it’s important to understand what impact it can have on employment and to take steps to ensure that workers benefit from the transition and aren’t left behind.

But what is the outlook for jobs in an electric transportation future? Can the EV transition support good, family- and community-supporting jobs and support a strong US economy? The fundamentals show there’s reason to be optimistic.

Building EVs requires workers too

This might not be obvious from the headlines or from talking points of some auto CEOs or politicians, but recent research efforts to understand how many workers it takes to build an EV have found that building an EV today requires similar, if not more, labor hours than building a conventional gasoline vehicle.

A recent study by researchers at Carnegie Mellon University (CMU) examined the labor requirements for manufacturing and assembling EV powertrain components, including the battery, compared to conventional gasoline vehicle powertrains. (More detailed coverage of the study can be found here). The researchers examined the actual manufacturing process and labor requirements, rather than generating estimates based off the number of parts in an EV (EVs have fewer parts than a gasoline vehicle).

Their conclusion:

The results “support the proposition that BEVs [battery electric vehicles] contain additional manufacturing content embedded in the batteries and electronic components that requires comparable levels of labor as ICEVs [internal combustion engine vehicles]”.

In other words, EVs don’t just make themselves, they require just as many workers as gasoline vehicles.

The CMU findings are not an outlier. Their results are supported by a separate study by FEV Consulting, commissioned by the Environmental Protection Agency (EPA), comparing the labor hours required to build the Volkswagen (VW) ID.4 electric vehicle and the VW Tiguan gasoline vehicle. The detailed analysis by FEV estimated that the EV powertrain for the VW ID.4 would take about 11 hours more labor to produce than the comparable Tiguan gasoline drivetrain.

Conclusion: building EVs can support a similar number of jobs as conventional gasoline vehicles.

Importance of ensuring quality jobs

Just because building EVs takes similar amounts of labor, doesn’t guarantee that those jobs will be good jobs. Nor does it mean existing auto workers will be treated fairly as the industry evolves and factories retool or relocate.

The current negotiation between the UAW (the union that represents autoworkers) and the Big Three (GM, Ford and Stellantis) is about the ongoing erosion of job quality in the auto sector. UAW workers have said they are fighting for better pay, benefits, and job security at a time when automakers have been making record profits and CEO pay has soared. But they have also cited the transition to EVs and the need to protect and support workers as factories adjust and new battery plants come online. There’s no reason that EV jobs can’t be stable, well-paying union jobs.

That’s why the battery plant workers being covered by the UAW contract is one of the issues that is part of the union negotiations. Some auto manufacturers are joining forces with battery technology companies in joint ventures to build new domestic battery manufacturing facilities. UAW wants to ensure these new facilities fall under UAW’s contract with the automakers and there are signs some progress is being made. UAW’s current contract negotiation is one clear and present opportunity for the industry to support a high standard for jobs in a modern auto manufacturing sector and in the clean economy more broadly.

On-shoring of the EV supply chain is a job growth opportunity

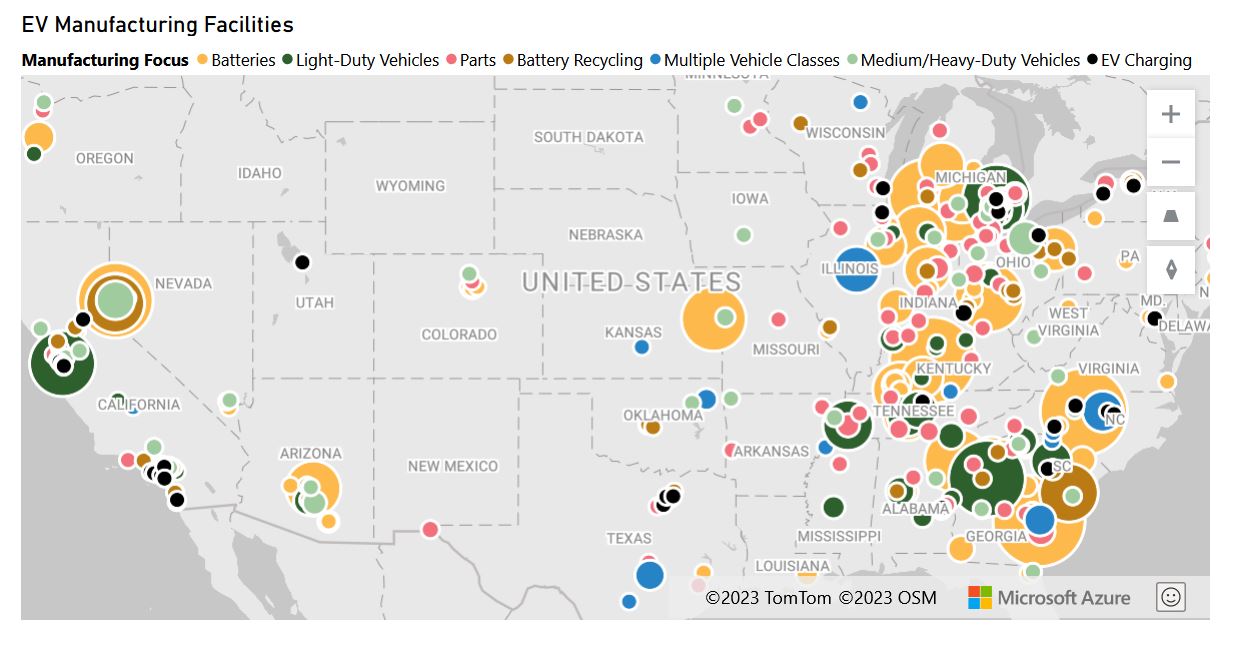

The good news from the studies noted above is that fundamentally, building EVs can sustain jobs in the automotive sector now and well into the future. We’re already seeing evidence of the job creation potential of EV investments with billions of dollars in announcements related to EV manufacturing, battery production, and battery recycling investment. (This handy tool tracks EV-related job announcements). But to take full advantage, we need to continue to bolster US EV battery production, manufacturing, and recycling, much of which currently is occurring outside the US.

Policies in the Bipartisan Infrastructure Law (BIL) and Inflation Reduction Act (IRA) are providing the shot in the arm the US needs to ramp up a domestic EV supply chain. For example, the BIL is providing billions of dollars to support the buildout of a public charging network to support EV adoption in the US, while the IRA has tax credits aimed at consumers to help support demand as automakers transition toward EVs. The most valuable tax credits are available to companies that manufacture vehicles and batteries in the US. These policies help automakers sell EVs, lower their investment risk, and drive domestic investment as the global transition to EVs is underway. The IRA has already helped catalyze billions of dollars in announced investments, including in U.S. battery production, from joint ventures between automakers and battery manufacturers to on-shoring of vehicle model production.

Not only is this important for creating jobs in the U.S. but making sure the US auto industry is well-positioned to be a leader in the global move to EVs over the next decade. Investments in the BIL and IRA are also an opportunity to support high labor standards and good jobs—which is why we joined with others in calling for EPA to establish a memorandum of understanding with the Department of Labor to support pathways for high-quality jobs in the green economy, a step the agencies took in July.

EVs are good for the economy, let’s make sure they are good for workers too

Overall, evidence points to positive economic benefits from a transition to electric transportation. The prices of EVs are dropping and are expected to match or beat up front costs of gasoline vehicles in the coming years. Savings from lower maintenance costs and the lower cost of charging a vehicle compared to a gasoline fill-up mean more money in consumers’ pockets. A report released by the Goldman School of Public Policy found on net, national employment could increase by more than 2 million jobs by 2035 with the rapid adoption of EV cars and trucks. Not to mention the benefits of cleaner air and lower climate emissions.

But not all sectors will experience job growth. As more and more EVs get on the road, new employment opportunities will continue to evolve and grow—like those associated with building out charging infrastructure for example. And in other sectors, like those in the petroleum and fossil fuel industry, the number of jobs will decline. Recent closures of refineries demonstrate how things can go wrong (as with one refinery in Philadelphia) and can also help inform how best to support workers going forward (as illustrated by a report from UC Irvine of a refinery closure in CA). Managing this transition is important and must be planned for in order to protect the communities and workers most impacted. One recent step forward on this is California’s recent commitment to develop a petroleum phase-out plan.

The EV transition is happening fast, and autoworkers are some of the first to grapple with the clean energy transition. Given the importance of this work for the future of our planet, it is essential the workers who will build these vehicles and their necessary components are fairly compensated. Thanks to investments in the Bipartisan Infrastructure Law and Inflation Reduction Act, there are more resources available to help The Big Three domestically produce these vehicles, without shortchanging workers. Anyone who is serious about a fair transition to a clean economy knows that it’s not just about creating new jobs in EV manufacturing, but about making sure that these jobs are high-quality jobs, with community-sustaining wages and benefits where workers have the free and fair choice to join a union.

That’s why UCS stands in solidarity with UAW. We believe setting a high standard for jobs in a modern auto manufacturing sector is a critical piece of achieving a just, clean energy economy.