Winter is once again here, bringing great festivities and respite via holidays, but also great worries to energy regulators, grid operators, and communities about dangerous winter storms that can spread across large parts of the United States and negatively affect electric grid reliability.

Power plants that use methane gas as a fuel will be relied upon to keep people warm and out of the dark, since gas plants are the country’s largest source of generating capacity. Unfortunately, these power plants have been far less reliable than expected in several extreme winter storms over roughly the last decade, and have failed disproportionately compared to other resources.

But how? What actually happens to gas plants, and the gas system writ large, that causes these disproportionately large failures during extreme winter storms, as compared to other resources? I’ll walk through some key causes of failure in this blog post, using a few illustrative examples. But first, some recent context.

Large-scale storms, large-scale grid failures

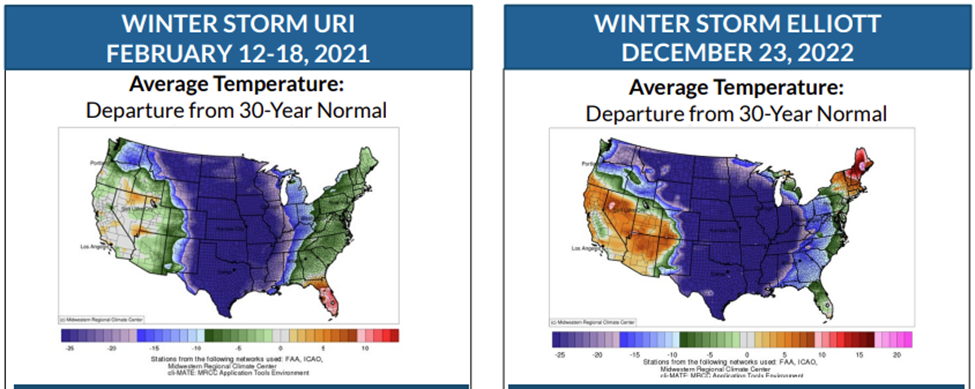

Over the last few years, the area of the country that has experienced such dangerous winter storms has been particularly large. Both Winter Storm Elliott in 2022 and Winter Storm Uri in 2021 caused major failures on the nation’s power grid on a historic scale, triggering power outages for millions of people during some of the most dangerous weather conditions of the year. During Uri, Texas was by far the most affected state, where 246 people died during the storm, nearly two-thirds from hypothermia.

The grid failures were mostly caused by power plants getting knocked offline amid the storms’ frigid cold temperatures. And while the areas affected by these latest two events were particularly large, the types of grid failures that arose weren’t particularly novel.

Since 2011, there have been five extreme winter storms that threatened the reliability of the grid, and the issues that ensued in all five of those storms were very similar. Large amounts of power plants–more than a thousand generating units in each of the two most recent cases–unexpectedly failed amid soaring energy demand, This triggered rolling blackouts in four out of the five storms. (Rolling blackouts are power outages caused by electricity supply shortages, which are different from other, more common types of power outages.)

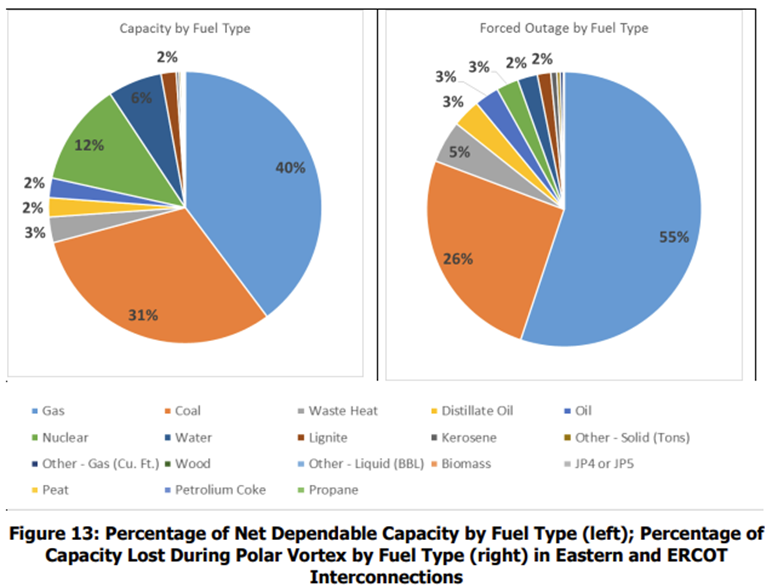

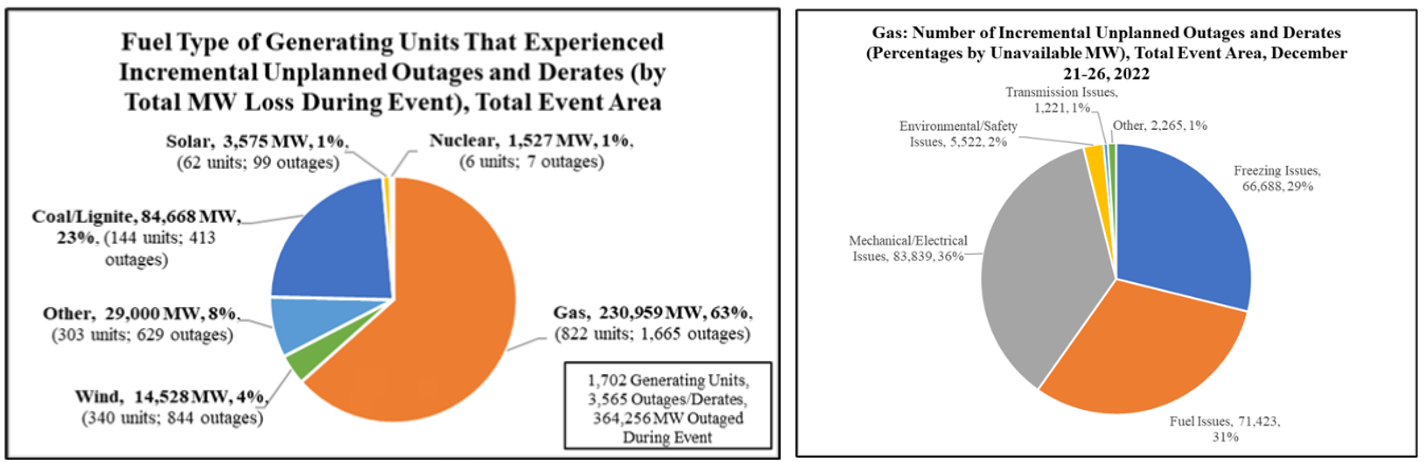

Another important commonality among all five storms: gas plants accounted for most of the generating capacity knocked offline, by far. This was not simply because there was more gas plant capacity on the grid than other sources. While gas plants did make up the largest percentage of installed capacity in each of the areas affected by the storms, they also made up a disproportionately larger percentage of the power plant failures. For example, during Winter Storm Elliott in December 2022, gas plants made up about 42% of the capacity in the storm-impacted area, but they also made up 63% of the capacity that failed during the storm. During the 2014 Polar Vortex (shown below), gas plants accounted for 40% of the generating capacity within the storm-impacted area, but 55% of the generating capacity that failed during the storm.

Recent extreme winter storms have triggered widespread gas plant failures, knocking many plants offline at the same time (often referred to as “correlated” plant outages). These storms can cause direct failures at the plants themselves, as well as indirect failures through disruptions of the gas system that delivers fuel to the plants. When a storm is severe enough, all the primary components of this delivery chain can be, and have been, affected—from the production wells, to the gas processing facilities, to pipelines, all the way to the power plants.

Plant equipment: freezing problems and other failures

In the aftermath of the recent grid-threatening winter storms, plant owners reported a very similar group of plant components as having frozen, including valves, water lines, and inlet air systems. This happened across events.

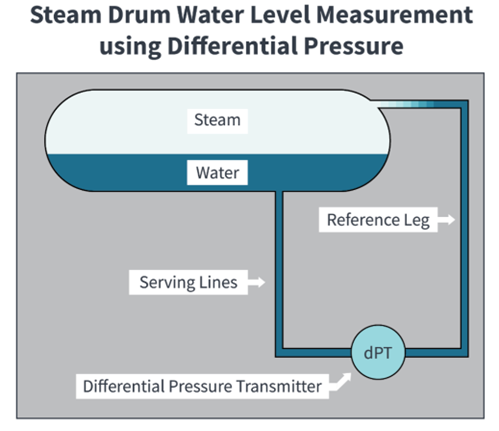

One of the freeze-vulnerable components repeatedly identified was sensing lines. These lines are pipes containing standing columns of water that are used for a wide array of applications, including the measurement of pressure levels, water levels, and water flow rates within the plants. Transmitters generally detect the pressure difference between two sensing lines and send that difference as an electrical signal to the plant’s control room. Many power plant operators reported frozen transmitters as the cause of plant failures during the recent storms, but in fact, it was often the sensing lines attached to the transmitters that froze.

The water within these sensing lines is standing, as opposed to flowing, making them particularly vulnerable to freezing, especially if the lines aren’t properly insulated. This can cause the transmitter to pick up an erroneous signal and shut down the plant altogether.

During Winter Storm Uri, for example, frozen feedwater sensing lines knocked a 568 megawatt gas-fired unit in Texas offline. Sensing line freezes were also the most common cause of generator outages in a Southwest storm a decade earlier.

Non-freezing failures of plant equipment also frequently occur in extreme cold, causing gas plants to shut down or operate at reduced capacity. The Federal Energy Regulatory Commission (FERC) and the North American Electric Reliability Corporation (NERC) generally categorize these types of issues as “mechanical/electrical,” which include wiring failures, mechanical wear of valves, and embrittlement of flexible seal materials like rubber and silicone. Like freezing issues, mechanical/electrical issues were a primary cause of power plant failures in all five of the recent storms.

Fuel issues: gas plants left without gas

Fuel issues have been another primary cause of gas plant failures during recent extreme winter storms. Unlike other thermal power plants–such as nuclear, coal, or oil plants–gas plants generally don’t store fuel on site, so they mostly rely on real-time delivery of gas via pipeline to be burned as soon as it arrives. This characteristic can result in a feedback loop of failures during frigid winter storms, since so many power plants depend on the gas system to get their fuel, but the gas system needs electricity from those power plants to produce, process, and transport that fuel.

Sudden drops in gas production have played a key role in fuel supply disruptions during a few of the recent storms. During Winter Storm Uri, for example, Texas gas production declined by 70%, and production in the lower 48 states overall sank by 28%. Rolling blackouts and other cold weather-related outages cut off power to gas infrastructure facilities, causing nearly a quarter of the decline in overall gas production.

However, the vast majority of the gas production decline during Uri, nearly 60%, was caused by more direct impacts on gas infrastructure such as equipment freezing, as well as other cold weather issues like poor road conditions (which can cut off access to gas facilities, causing production to shut down).

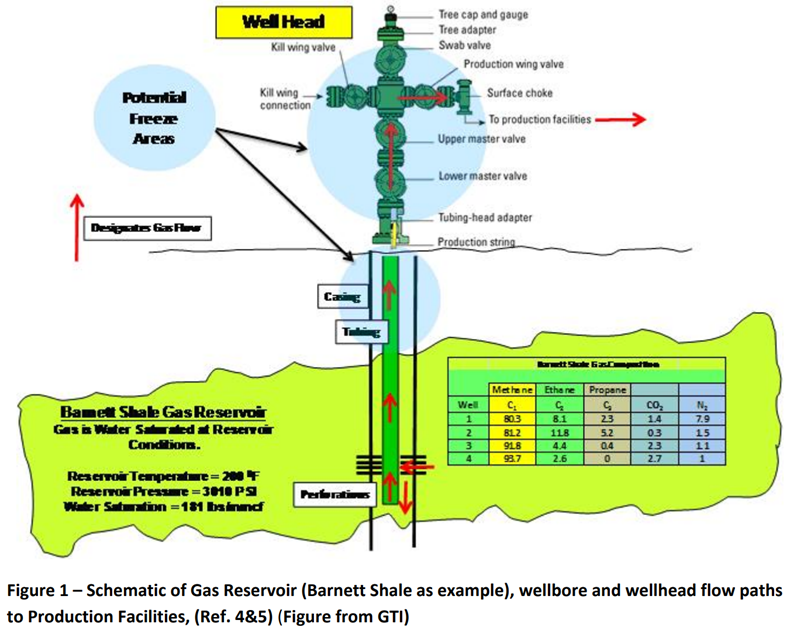

A prominent contributor of gas production declines during some of the recent storms was “freeze-offs”, when water produced alongside gas freezes up within gas wells, wellheads, and other ancillary equipment, blocking the flow of gas. For example, during a 2011 winter storm in the Southwest, gas production in the Permian basin–located within New Mexico and Texas–dropped by more than 50% in just a few days. Among the gas processing companies that responded to a post-storm survey, 85% of the shortfall was attributed to freeze-offs at equipment further upstream, such as gas wellheads.

Significant unexpected production declines ensued in the latest major storm as well, cutting off fuel supply to gas plants. During Winter Storm Elliott, gas production in the Marcellus and Utica shale formations in the Appalachian Basin dropped by 23% and 54%, respectively.

Gas production drops, however, aren’t the only cause of gas plant fuel shortages. Constraints and equipment failures on the gas transportation system can leave gas plants without fuel, even when those plants are prioritized for fuel supply via contracts. And on very cold days, demand for gas can outstrip supply even without sudden drops in production, leaving gas plants without fuel. Fuel issues arising from production declines, pipeline issues, and other failures were responsible for 31% of the lost gas capacity during Winter Storm Elliott. In that storm, gas capacity made up 63% of the total power plant outages, and 83% of the fuel-related plant outages.

Looking ahead

Gas has been proven again and again to be vulnerable to failure in extremely cold weather. This vulnerability creates dangerous risks given the cascading and correlated nature of system failures that cause many gas plants to go offline at the same time. Building more gas plants or keeping aging plants online won’t solve the winter problem due to a host of reasons, including the carbon dioxide and methane emissions associated with gas plants. These emissions are driving the very climate change that is making extreme weather events worse.

Clean energy solutions are readily available to bolster winter grid reliability while mitigating climate change at the same time. Many grid modeling studies have shown how the United States can get at least 80-90% of its electricity from renewables, with strong net benefits. The country must diversify away from gas and other fossil fuels in the power sector and transition to clean electricity. By making this transition, the country can strengthen the reliability and resiliency of the grid, while ending the vicious cycle of burning the very fossil fuels that contribute to making weather more extreme.

Gas plants can fail in extreme summer weather, too. Read more here.