Earlier this month, the California Air Resources Board held a workshop on the use of hydrogen combustion engines in trucks in California as part of an agreement with the Truck and Engine Manufacturers. It was clear from the workshop that industry is interested in extending the lifetime of their investments in combustion engine manufacturing regardless of the harm it would cause to the environment or the public. While industry tried to paint hydrogen combustion engines as a “bridge” technology to hydrogen fuel cells, their own presentations undermined that very point—instead, this path is a clear dead end. We need to make sure regulators like EPA and CARB restrict its usage before it gains a fossil-fueled foothold in the marketplace.

Below I walk through the falseness of industry’s narrative and why hydrogen combustion is the heavy-duty sector’s last ditch attempt to avoid responsibility for the harms of their products.

Hydrogen combustion trucks still have tailpipe emissions

No matter how you frame it, hydrogen combustion still means combustion, and that means byproducts. While pure hydrogen gas may contain no carbon, impurities in the fuel (including methane) and hydrocarbons in the engine lubricant mean that a hydrogen combustion engine still produces CO2 as an output, as was noted by Daimler Trucks in their presentation.

Importantly, however, CO2 is not the only greenhouse gas directly produced: N2O is a greenhouse gas 265 times more potent than CO2, directly produced as a combustion byproduct. As noted by Southwest Research Institute in its proposal, these emissions can be quite high and require additional control. This gas is regulated by EPA under its heavy-duty vehicle program, but controls will only be implemented to the extent that EPA requires them under rigorous testing procedures and strong standards.

When it comes to smog-forming NOx emissions, industry made really clear at the workshop that these trucks will end up polluting just as much as diesel trucks. Hydrogen combustion engines release less NOx directly than comparable diesel engines—however, industry was quick to point out that rather than necessarily lead to fewer overall emissions, this would simply justify truck manufacturers’ deployment of less advanced emissions control technologies than their diesel truck counterparts. In other words, manufacturers are going to squander any opportunity for emissions gains because EPA’s heavy-duty engine standards make no distinction between fuel, and manufacturers will always pollute as much as federal limits allow them to get away with.

Particulate emissions pose the same problem. While prototype spark-ignition hydrogen engines have shown reductions in soot compared to diesel engines, the more efficient direct-injection hydrogen combustion engines that industry wants to deploy have been shown to have substantially higher particulate matter emissions than those prototype designs, as we noted for EPA in our comments on their Phase 3 vehicle proposal. Unfortunately, no data was presented on these engines at the workshop.

Hydrogen is produced from fossil fuel, and hydrogen combustion is a terribly inefficient use for it

As my colleague Sam Wilson noted in a recent fact sheet on hydrogen-powered trucks, the tailpipe is not the only source of impacts from hydrogen-fueled vehicles. This was reiterated at the workshop by Argonne National Lab staff, who found in their own research that hydrogen combustion trucks could lead to an increase in heat-trapping emissions. Why is that? Because today, virtually all hydrogen produced comes from natural gas.

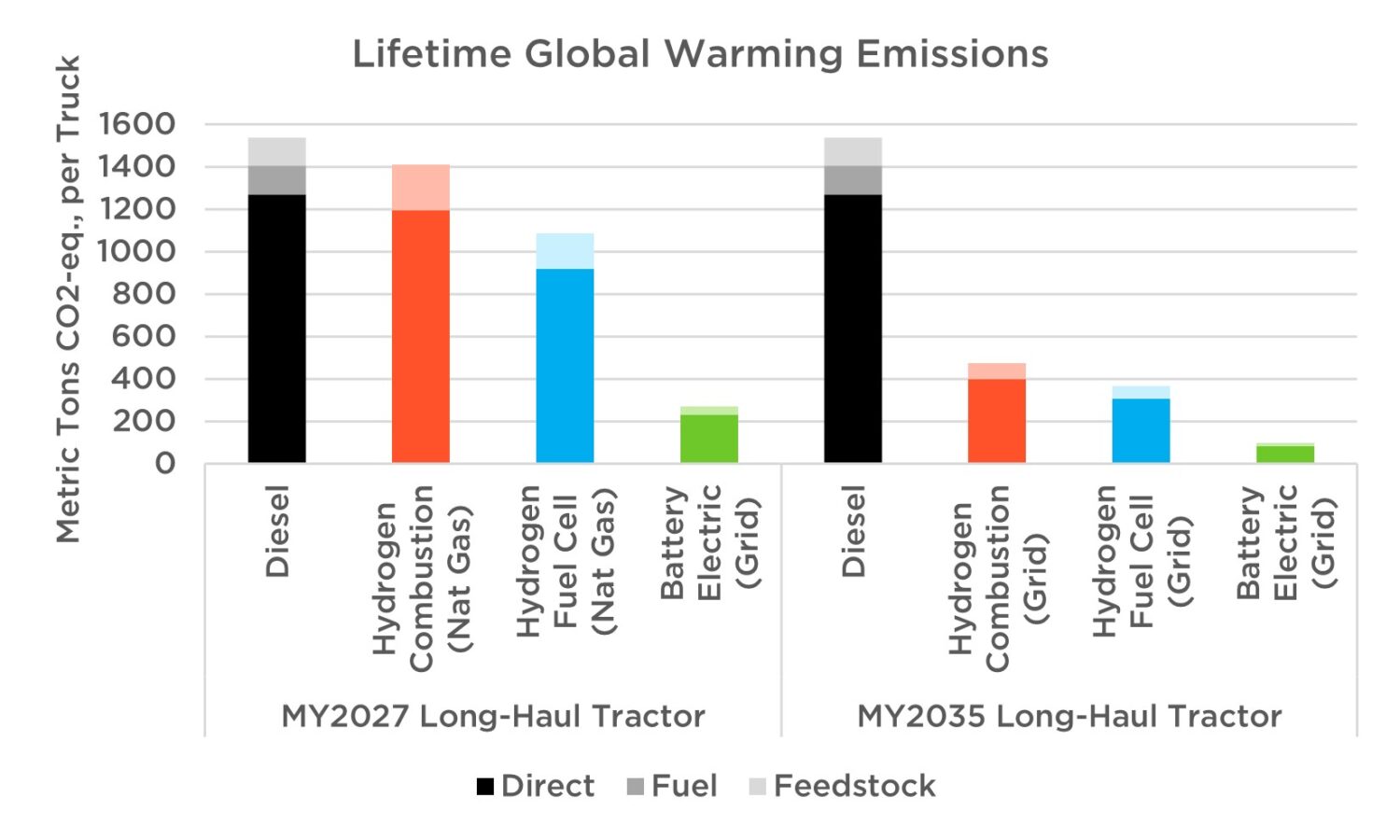

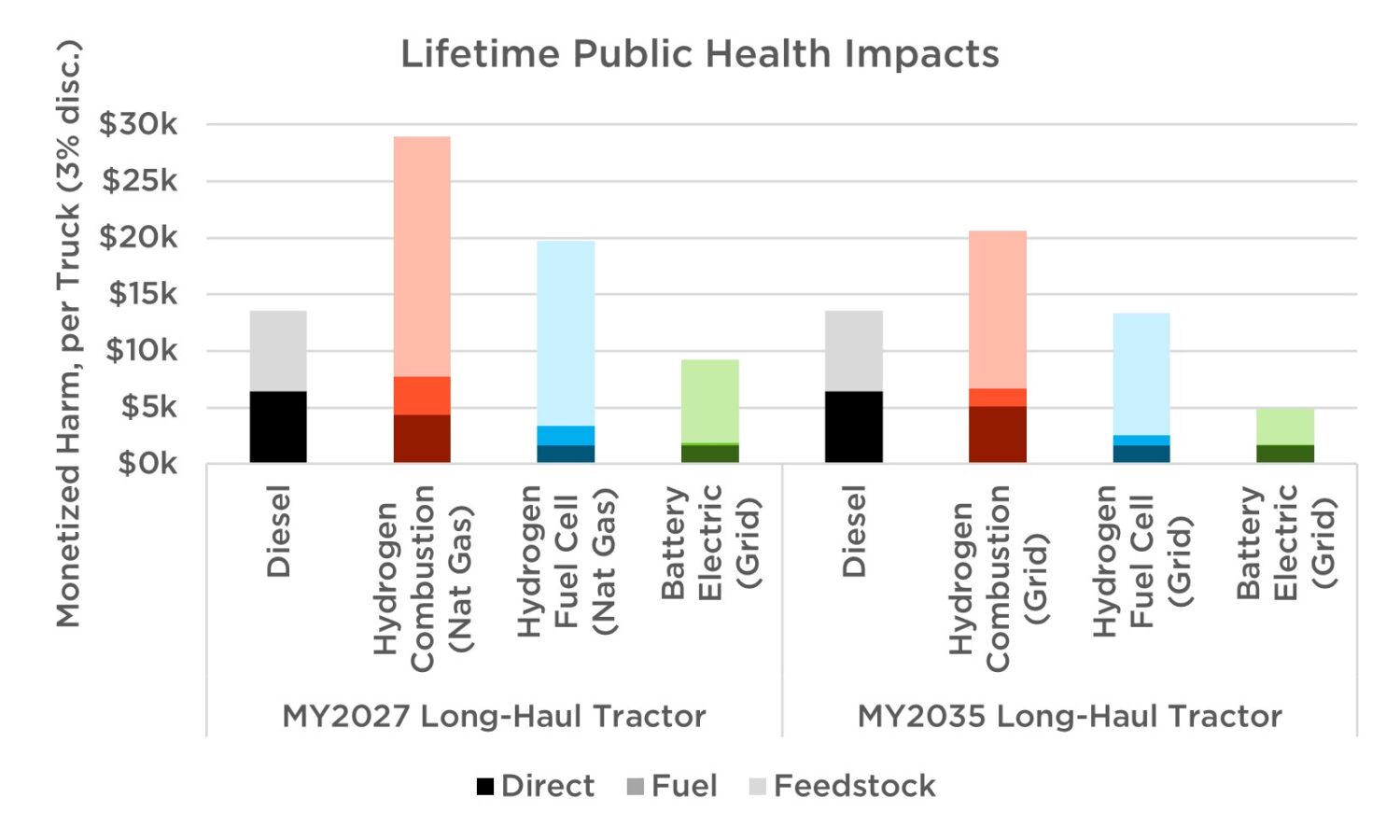

Our own analysis can shed some additional light on the problem of hydrogen combustion. From a climate perspective, hydrogen’s reliance on natural gas as a source means massive emissions upstream of the truck thanks to fugitive methane emissions. But from a public health perspective, the ubiquity of fossil hydrogen means that you are simply replacing the harms of one fossil fuel with another. All of the industrial pollution associated with the production and distribution of natural gas yields massive amounts of pollution, and then you combine that with the emissions related to the reforming process to actually turn that gas into hydrogen. And then all of these polluting steps are compounded by the fact that you’re just burning the fuel, which is just terribly inefficient.

The story isn’t dramatically improved in the future, either. Natural gas is likely to continue to be the dominant source of hydrogen in the near-term; however, even electrolysis fueled by a future, clean grid (90 percent reduction in global warming emissions) would yield health impacts even worse than diesel because its such an inefficient use of energy. Electrolysis is already a relatively energy-intensive process to create hydrogen, and additional energy is required to then compress and pre-cool the hydrogen for before it’s distributed as a compressed gas. In total this amounts to requiring around twice the energy input as you get out. Hydrogen is then distributed via tanker truck, which is much less efficient than pipelines but more cost-effective for low volumes. Finally, in a hydrogen combustion truck you have to deal with another major inefficiency, the combustion process itself, which is around 50 percent thermal efficiency but then has additional energy losses related to the transmission and axles.

Even if you were able to make hydrogen with electricity 100 percent generated by sunshine, it’s just far more efficient to just use that cleaner electricity to fuel battery-electric trucks—our data shows more than 4 times the electricity would be required per mile for a hydrogen combustion long-haul truck.

The hydrogen combustion advocates at the workshop have tried to sell this as a solution, but it appears the cure may be even worse than the disease!

A true “bridge to nowhere”

Obviously from a health and environmental perspective, hydrogen combustion is a disaster for the public. But does this even make sense on the surface for the folks yearning for it to promote the deployment of hydrogen infrastructure?

One of the points that came up at the workshop over and over again was that hydrogen combustion will spur the deployment of a hydrogen fueling network, which can then be used in hydrogen fuel cell trucks, which have zero tailpipe emissions. But as was raised during the Q&A session, there is a fundamental flaw in this logic, which industry ignored throughout the presentation.

A key reason industry claimed that hydrogen combustion was so much easier to deploy than fuel cell trucks was that combustion is less susceptible to impacts from impurities, while fuel cells rapidly degrade when fueled with low-quality hydrogen. But, this makes no sense—if your hydrogen infrastructure is filled with low-quality hydrogen, you’ve done nothing but build out a hydrogen network useless for fuel cell trucks. If instead you ensure your network is primarily high-purity hydrogen fuel, then your market is no different than it would be for fuel cells.

Having a completely distinct type of hydrogen vehicle doesn’t fundamentally change the infrastructure challenge that has plagued the sector for decades. You can’t solve the chicken and egg problem with a goose!

And if you’re a fleet operator looking at hydrogen as a transportation fuel, it makes no sense to burn it anyway, purely as a business case. This was highlighted by both Toyota and Hyundai in their presentations at the workshop, and this is consistent with economic analysis from the International Council on Clean Transportation that showed just how fundamentally terrible hydrogen combustion trucks pencil out. Industry may want operators to keep buying engines, but it just doesn’t make any sense, so it’s hard to see how the market would grow (without, say, cross-subsidization by engine manufacturers to prolong the sale of their products).

We don’t need more combustion trucks

Of course, one of the biggest fallacies in industry’s approach to hydrogen combustion was the notion that there is any need for the trucks in the first place. CARB’s Advanced Clean Trucks (ACT) rule has helped push electric trucks out the door, and now they’re outselling the state’s requirements. More states continue to hop on the bandwagon, with Maryland the most recent state to adopt the program. Industry has tried to manufacture concern around the readiness for Class 8 tractors to be electrified as a reason for pushing its hydrogen combustion engines, but the targets for tractors under ACT can be met almost exclusively through the deployment of regional haul EVs, exactly the same vehicles being sold by industry today. And the infrastructure needed to keep pace with the growth of the industry is modest, at best.

UCS analysis of EPA’s nationwide proposal shows that its own rule can be similarly met with the electrification of Class 8 vocational and day cab tractors and the deployment of more efficient diesel vehicles already in the works as a result of the prior Phase 2 rule currently on the books. Because EPA’s rule are technology-neutral rather than requiring the deployment of the best technologies to reduce emissions, manufacturers could comply with the agency’s proposal with the deployment of more efficient diesel-powered vehicles with as little as less than 10 percent of Class 8 tractor sales in 2032 electric in states that haven’t adopted ACT. And that would be further eroded with EPA’s posture that credits hydrogen combustion vehicles identically to battery-electric vehicles.

No matter the stringency of the agency’s heavy-duty regulation, set to be finalized in the coming months, the agency’s current approach to credit hydrogen combustion as having 0 g CO2/ton-mile emissions is not just preposterous, as our analysis above proves—it risks further exacerbating harms from the freight sector, creating communities of “haves” in ACT states where electric trucks are flooding the market and “have nots” in states where the federal rules are so lax that electrification is barely a trickle.

EPA must close the hydrogen combustion loophole

As EPA gets ready to finalize the next phase of its heavy-duty greenhouse gas rules, it faces an opportunity to strengthen the holes in its proposal. A stronger rule would provide a better path to drive emissions reductions from the freight sector and set us on a path to truly zero emissions. Regardless of the rule’s stringency, however, it’s clear that hydrogen combustion is a dead-end technology.

CARB’s workshop laid bare that the folks interested in hydrogen combustion are the fuels industry and manufacturers looking to prolong their combustion engine business. This push is at odds with EPA’s public health mandate and the companies’ own stated commitments to targeting zero emissions.

In order to put us on a path to zero emissions from the heavy-duty vehicle sector, EPA must consider the full impacts of hydrogen combustion trucks and end its proposal to credit such vehicles as 0 g CO2/ton-mile. If the agency doesn’t close this loophole, it could end up promoting a technology that is even more harmful than diesel.

Hydrogen combustion isn’t just a “bridge to nowhere”—it’s driving in the wrong direction. EPA has to be the “GPS” to get industry back on track, or we risk being permanently lost in a fossil fuel cul-de-sac.