Electric vehicles (EVs) are a cleaner option than gasoline alternatives and are essential for reducing emissions that cause climate change and illnesses. UCS has estimated the minerals needed to electrify passenger vehicle sales in the United States and our recent report has exciting findings– we can electrify using less minerals than previously thought!

Our estimates show that with the right policies and the cooperation of industry, we can continue electrifying our cars and trucks using nearly 50% less newly mined lithium than expected from now until 2050.

How? By investing in battery recycling, EV efficiency, charging, battery innovation, and more choices of transportation modes. Essentially, the amount of minerals needed to create our vehicles is reduced through:

- Increased EV efficiency: Making EVs energy efficient reduces battery size requirements by using less energy per mile.

- Battery innovation: Higher energy density and battery chemistry innovations can lead to lower amounts of key minerals used per EV.

- Charging availability: Convenient, fast, and reliable public charging access reduces the need for extremely long-range EVs that require larger batteries.

- Increased mobility options: Convenient and affordable transportation alternatives, including public transit, walking, and biking, along with smarter town planning allows households to rely on fewer personal vehicles.

These attainable strategies reduce the overall minerals needed to electrify and make it easier to meet demand with recycled materials.

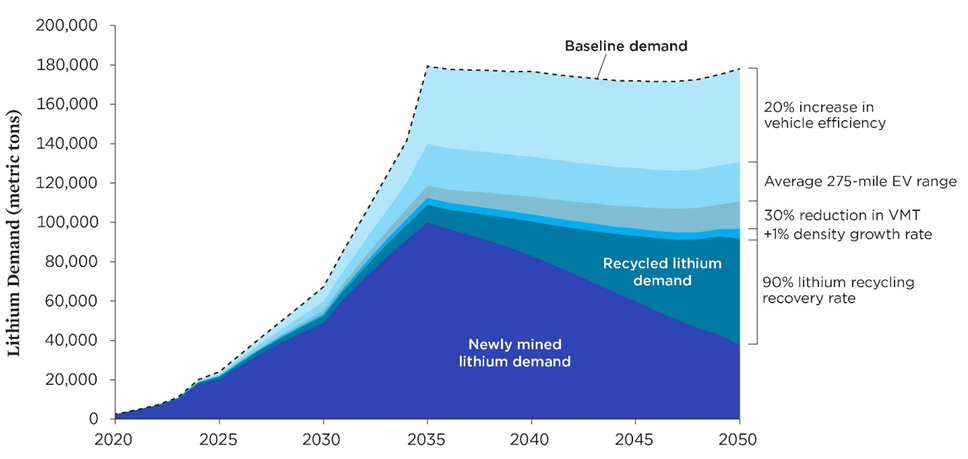

Minerals used in batteries include lithium, cobalt, nickel, copper, aluminum, and graphite, but in our study, we took a closer look at a special one: lithium. The graph below demonstrates the reduced demand peak of lithium when these mineral conservation measures are taken, as well as the declining need for new mining as recycled minerals become available.

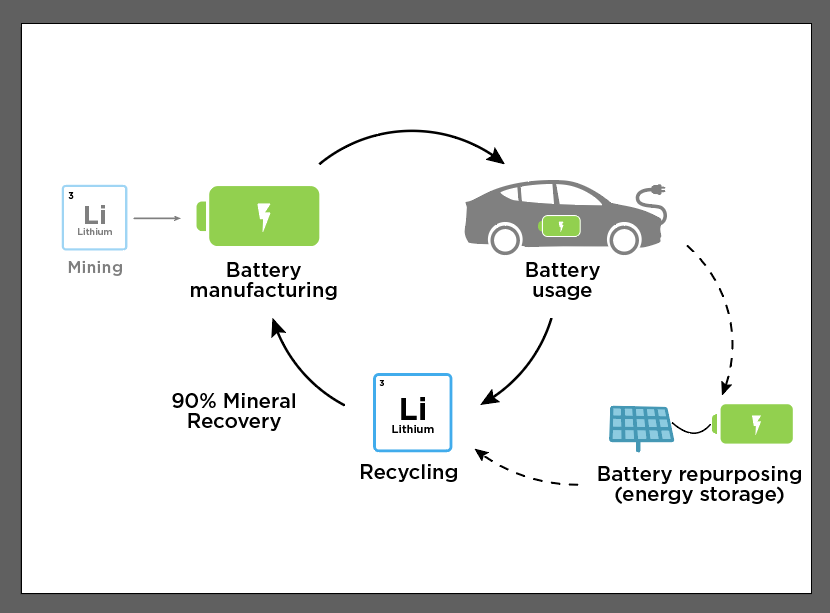

Recycling and lithium recovery is key to a sustainable supply chain

Recycling can enable the continued use of minerals indefinitely. An EV battery retired today can be recycled and the recovered minerals go into the next generation of EVs. Our findings show that with high recovery rates, recycled minerals can offset nearly 50 percent newly mined mineral demand from now until 2050. That is enough lithium for 180 million typically sized EVs!

Strong policy is needed to ensure batteries are recycled and lithium is recovered. The recycling industry is ramping up to accommodate EV battery retirements, but because lithium isn’t as valuable as cobalt and nickel, it isn’t always recovered. Assuming business as usual, we estimate that a much smaller 26 percent of lithium demand would be met with recycled material in 2050.

The European Union implemented a requirement for EV producers to be responsible for recycling batteries and recovering increasing percentages of lithium, cobalt, nickel, and copper. We think the United States should follow in their footsteps. While recycling requirements are being developed in states such as California and New Jersey, the bills haven’t yet included essential mineral recovery rate requirements.

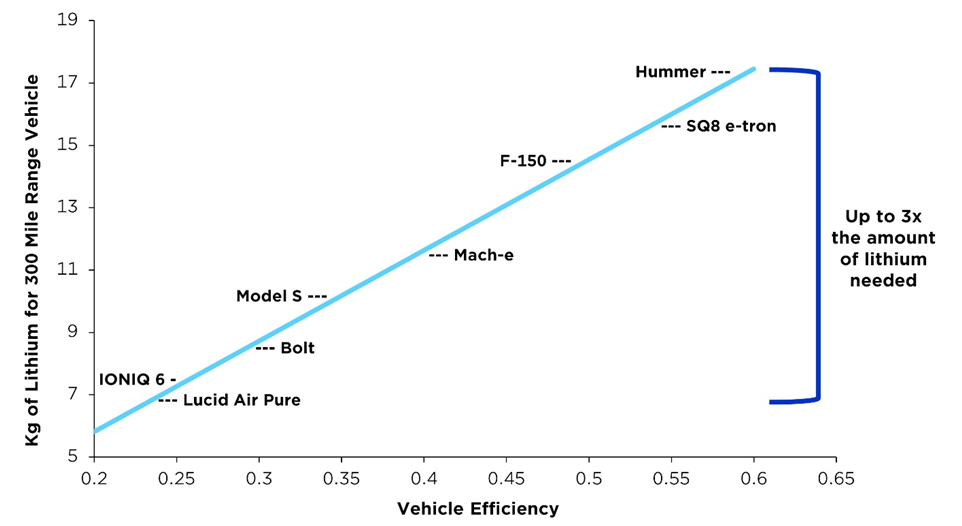

More efficient EVs mean less minerals and lower costs

A more efficient EV needs less energy from its battery per mile. A more efficient EV means you need a smaller battery to have the same EV range. An efficient EV is also great for the consumer in that it can lower the upfront cost of the vehicle and lower the cost of charging.

Vehicle efficiency can also impact long-term mineral demand. Our analysis shows that if passenger vehicles increase efficiency by 20%, we will need 22% less lithium from now until 2050. Currently, EV energy efficiency is all over the spectrum, and it is not clear if vehicles will reach the desired efficiency without policy intervention. The most efficient EV currently available is the Lucid Air Pure, requiring 23 kilowatt-hours (kWh) per 100 miles, followed by the Hyundai IONIQ 6, requiring 24 kWh per 100 miles. Efficiency has a sizeable impact on battery pack lithium requirements and the following graph shows how EVs on the market today compare.

Convenient and fast EV charging can influence the desired range

EV range also largely influences battery size. EV range is the number of miles an EV can go on a full charge. Range needs and preferences depend on commute length, terrain, weather, and the accessibility, availability, and speed of charging. The typical US driver drives 29 miles per day, but consumers typically consider longer and more infrequent drives, such as road trips, when purchasing a car.

Our research demonstrates that slightly lowering EV model vehicle range to an average of 275 miles (2-3 hours of driving), could reduce new lithium demand by 20 percent by 2050, compared to increasing average vehicle ranges to 325 miles.

As publicly accessible charging infrastructure is built up around the United States and public charging speeds get faster, longer EV ranges will likely not be as frequently needed. This is beneficial to the sustainability and resiliency of our transportation system as well as to consumers—a smaller range in an efficient EV results in a smaller battery, reducing the vehicle cost and the overall mineral needs.

Increasing transportation options is critical

Ultimately, demand for minerals used in EV batteries depends on the size of vehicle batteries and the number of vehicles sold. Making it easier for households to meet their travel needs without using a private car for every trip by investing in convenient and affordable transportation alternatives, along with smart community planning, can allow households to rely on fewer personal vehicles and reduce overall demand for new vehicles. We’ve estimated that the resulting decrease in vehicle sales could result in lithium demands decreasing by 15 percent by 2050. To achieve a more clean, equitable, and multimodal transportation system, we must take the following actions:

- Greatly expand transportation options that offer abundant access to everywhere we need to go.

- Make transportation planning decisions through an equity and climate lens.

- Make decisionmaking in transportation and land use planning more democratic, accessible, and equitable.

These approaches create a more secure and sustainable supply chain

Electrifying our transportation system has sizeable benefits—we can reduce climate-changing emissions and air pollutants that cause serious health problems. But how we get to fully electric matters. By minimizing the amount of overall electricity and newly mined minerals needed to electrify, we can make an even more sustainable, resilient, and just transportation system. Luckily, this future is within reach and can be achieved through the collaborative systems-wide strategy outlined above, including sustainability-driven EV product development, transportation planning, and required EV battery recycling.