Lithium-ion batteries are essential for decarbonizing transportation through electric vehicles and building a resilient, renewable energy grid through energy storage batteries. The grid energy storage industry represents a much smaller fraction of the lithium-ion battery market than electric vehicles, but it too has a responsibility to ensure batteries are responsibly and sustainably produced and then productively recirculated at end-of-life.

Nearly every part of a renewable energy grid can be circular, with all outputs circulating back as inputs in a regenerative cycle. The battery life cycle can work this way too, if the valuable metals in batteries are recovered and reused. However, lithium-ion battery supply chains are not yet circular. Increasing the reuse and recycling of batteries at their end of life is essential to increasing the sustainability of batteries and creating a circular economy.

Recycling must ramp up

There are huge opportunities for recycling to decrease the need for newly mined materials in batteries. By 2050, battery recycling could supply 22 to 27% of lithium, 40 to 46% of nickel, and 45 to 52% of cobalt needed for electric vehicles in the US. The US is building up the infrastructure needed to fully capture this value. Currently, the US only has about 7% of the global recycling capacity while China has 80%.

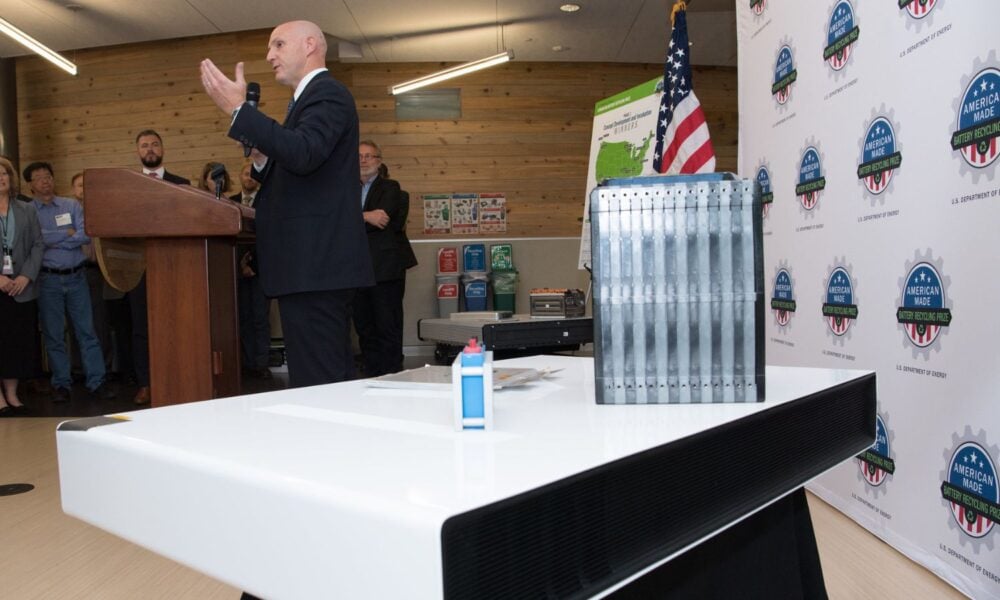

The US government is also committed to bolstering domestic recycling. Since 2019, the Department of Energy’s ReCell Center has been researching effective and affordable battery recycling technology. The federal Bipartisan Infrastructure Law dedicated $3 billion to a battery material processing program and $3 billion for domestic battery manufacturing and recycling; $200 million to a battery design, recycling, and reuse program; $110 million for battery collection and recycling programs; $15 million on retailer battery collection programs; and $10 million for the Lithium Ion Battery Recycling Prize. Recently, a total of nearly $74 million dollars of funds was awarded for research, development, and demonstration of 10 recycling and repurposing projects. Companies leading the domestic battery recycling industry show high material recovery rates of 95-98%.

Sustainable supply chain solutions exist

In many circular systems, problems = solutions. The same goes for the energy storage battery supply chain. Governments and industry can leverage these five tactics to move energy storage batteries towards a more circular end-of-life stewardship.

- Require producer take-back. In order to ensure batteries are recycled, it is essential to assign a party responsible. A producer take-back model requires the battery manufacturer ensures batteries are repurposed or recycled at the end of their life if they are no longer wanted by the owner. The California legislature convened a stakeholder group to develop policy to reach 100% battery recycling in the state, which included producer take-back as a topline recommendation, mirroring the policy of the European Union Battery Directive.

- Support safe, efficient, and cost-effective battery transportation. Because batteries can be hazardous if improperly handled, transporting them involves additional regulations and can constitute 40 to 60% of battery recycling costs. Governments can fund battery transportation safety research and worker training programs and can facilitate safe and efficient handling by encouraging manufacturers to clearly display battery components, chemical compositions, and health status. Regulators can also enact new waste categories specifically for batteries, which can make transporting used batteries to reuse or recycling centers safer and more cost-effective.

- Encourage battery manufacturers to design for disassembly. The government can urge battery makers to employ design standards that facilitate disassembly, quality testing at end-of-life, and repurposing. This could accelerate the reuse of used electric vehicle batteries in grid energy storage. More than 200 gigawatt-hours of used electric vehicle batteries will be available for energy storage reuse by 2030, which would satisfy projected grid storage battery demand.

- Increase access to information. The US can further spur battery reuse and recycling by encouraging companies to display information clearly on all used batteries, including the type of chemistry and the results of quality tests on the battery’s health and remaining capacity.

- Invest in domestic battery recycling research and infrastructure. The US can continue to provide funding for research labs and companies developing and scaling domestic recycling. Additional funding for lithium-ion battery recycling research and projects can also help ensure that the emerging industry continues to meet and exceed standards for worker safety and environmental sustainability.

Effective policy, industry commitment, and public awareness can help address the issues of raw materials and manufacturing challenges alongside the battery waste issue. The secret? Unlocking battery reuse and recycling.

Fleets of batteries—acres and acres of unassuming stationary metal boxes—are a key to unlocking the renewable energy future. But are batteries, themselves, renewable? Can they be reused or recycled at the end of their life? Where do their raw materials come from, and how can we ensure their valuable contents are recovered rather than wasted? Click to learn more!

How are Lithium-ion Batteries that Store Solar and Wind Power Made?

Challenges and Opportunities in Mining Materials for Energy Storage Lithium-ion Batteries

And what about the solar panels and wind turbines, which generate the electricity that batteries store? Check out our previous posts on solar panel and wind turbine lifecycles!