An NRC Special Inspection Team (SIT) conducted an inspection at the LaSalle Nuclear Plant this spring to investigate the cause of a valve’s failure and assess the effectiveness of the corrective actions taken.

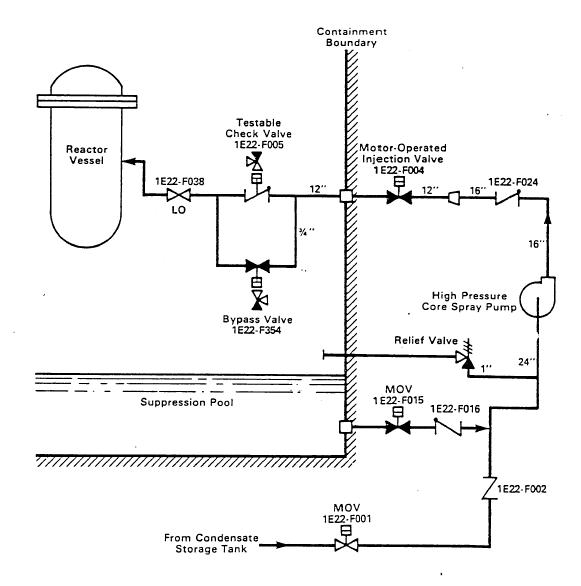

The two units at Exelon Generation Company’s LaSalle County nuclear plant about 11 miles southeast of Ottawa, Illinois are boiling water reactors (BWRs) that began operating in the early 1980s. While most of the BWRs operating in the U.S. are BWR/4’s with Mark I containment designs, the “newer” LaSalle Units feature BWR/5’s with Mark II containment designs. The key distinction for this commentary is that while BWR/4’s employ steam-driven high pressure coolant injection (HPCI) systems to provide makeup cooling water to the reactor core in event that a small pipe connected to the reactor vessel breaks, the BWR/5’s use a motor-driven high pressure core spray (HPCS) system for this safety role.

The Event

Workers attempted to refill the Unit 2 high pressure core spray (HPCS) system with water on February 11, 2017, following maintenance and testing of the system. The Unit 2 reactor was shut down for a refueling outage at the time and this downtime was used to inspect emergency systems, like the HPCS system.

The HPCS system is normally in standby mode during reactor operation. The system features one motor-driven pump that supplies a design makeup flow rate of 7,000 gallons per minute to the reactor vessel. The HPCS pump draws water from the suppression pool inside containment. In event that a small-diameter pipe connected to the reactor vessel broke, cooling water would leak out but the pressure inside the reactor vessel would remain too high for the array of low-pressure emergency systems (i.e., the residual heat removal and low pressure core spray pumps) to function. Water pouring from the broken pipe ends drains to the suppression pool for re-use. The motor-driven HPCS pump can be powered from the offsite electrical grid when it is available or from an onsite emergency diesel generator when the grid is unavailable.

Fig. 1(Source: Nuclear Regulatory Commission)

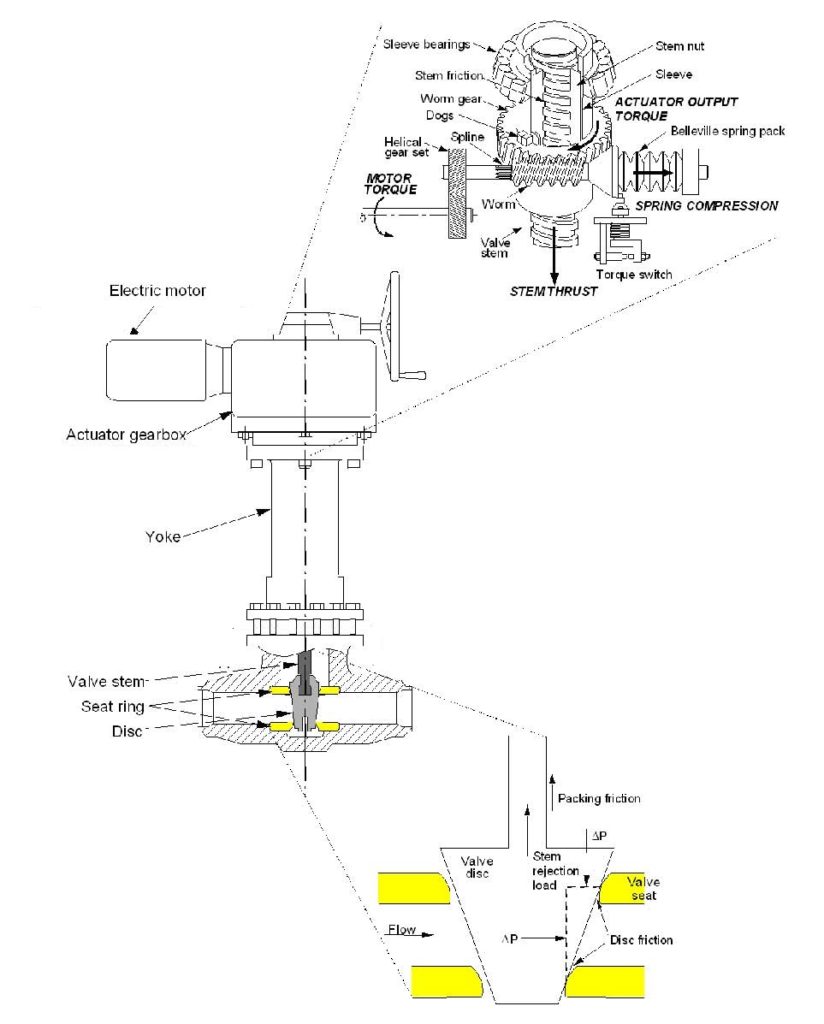

Workers were unable to fill the piping between the HPCS injection valve (1E22-F004) and the reactor vessel. They discovered that the disc had separated from the stem of this double disc gate valve manufactured by Anchor Darling and blocked the flow path for filling the piping. The HPCS injection valve is a normally closed motor-operated valve that opens when the HPCS system is actuated to provide a pathway for makeup water to reach the reactor vessel. The motor applies torque that rotates a screw-like stem to raise (open) or lower (close) the disc in the valve. When fully lowered, the disc blocks flow through the valve. When the disc is fully raised, flow through the valve is unobstructed. Because the disc became separated from the stem in the fully lowered position, the motor might rotate the stem as if to raise the disc, but the disc would not budge.

Fig. 2 (click to enlarge) (Source: Nuclear Regulatory Commission)

Workers took a picture of the separated double disc after the valve’s bonnet (casing) was removed (Fig. 3). The bottom edge of the stem appears at the top center of the picture. The two discs and the guides they travel along (when connected to the stem) can be seen.

Fig. 3 (Source: Nuclear Regulatory Commission)

Workers replaced the internals of the HPCS injection valve with parts redesigned by the vendor and restated Unit 2.

Background

The Tennessee Valley Authority submitted a report under 10 CFR Part 21 to the NRC in January 2013 about a defect in an Anchor Darling double disc gate valve in the high pressure coolant injection system at their Browns Ferry nuclear plant. The following month, the valve’s vendor submitted a 10 CFR Part 21 report to the NRC about a design issue with Anchor Darling double disc gate valves that could result in the stem separating from the discs.

In April 2013, the Boiling Water Reactor Owners’ Group issued a report to its members about the Part 21 reports and recommended methods for monitoring the affected valves for operability. The recommendations included diagnostic testing and monitoring the rotation of the stems. Workers performed the recommended diagnostic testing of HPCS injection valve 2E22-F004 at LaSalle during 2015 without identifying any performance issues. Workers performed maintenance and testing of HPCS injection valve 2E22-F004 on February 8, 2017, using the stem rotation monitoring guidance.

In April 2016, the Boiling Water Reactor Owners’ Group revised their report based on information received from one plant owner. Workers had disassembled 26 potentially susceptible Anchor Darling double disc gate valves and found problems with 24 of them.

In April 2017, Exelon notified the NRC about the failure of HPCS injection valve 2E22-F004 due to separation of the stem from the discs. Within two weeks, a Special Inspection Team (SIT) chartered by the NRC arrived at LaSalle to investigate the cause of the valve’s failure and assess the effectiveness of the corrective actions taken.

SIT Findings and Observations

The SIT reviewed Exelon’s evaluation of the failure mode for the Unit 2 HPCS injection valve. The SIT agreed that a part within the valve had broken due to excessive force. The broken part allowed the stem-to-disc connection to become steadily more misaligned until eventually the discs separated from the stem. The vender redesigned the valve’s internals to correct the problem.

Exelon notified the NRC on June 2, 2017, of its plan to correct 16 other safety-related and important to safety Anchor Darling double disc gate valves that may be susceptible to this failure mechanism during the next refueling outages of the two LaSalle units.

The SIT reviewed Exelon’s justifications for waiting to fix these 16 valves. The SIT found the justifications to be reasonable with one exception—the HCPS injection valve on Unit 1. Exelon had estimated the number of times that the Unit 1 and the Unit 2 HPCS injection valves had been cycled. The Unit 2 valve was original equipment installed in the early 1980s while the Unit 1 valve had been replaced in 1987 following damage due to another cause. Exelon contended that the greater number of strokes by the Unit 2 valve explained its failure and justified waiting until the next refueling outage to address the Unit 1 valve.

Citing factors like unknown pre-operational testing differences between the units, slight design differences of unknown consequence, uncertain material strength properties, and uncertain differences in stem-to-wedge thread wear, the SIT concluded “that it was a matter of “when” and not “if” the 1E22-F004 valve would fail in the future if it had not already failed.” In other words, the SIT did not buy the delayed look at the Unit 1 valve.

Exelon shut down LaSalle Unit 1 on June 22, 2017, to replace the internals of HPCS injection valve 1E22-F004.

NRC Sanctions

The SIT identified a violation of Criterion III, Design Control, of Appendix B to 10 CFR Part 50 associated with the torque values developed by Exelon for the motors of HPCS injection valves 1E22-F004 and 2E22-F004. Exelon assumed the valves’ stem to be the weak link and established motor torque values that would not over-stress the stem. But the weak link turned out to be another internal part. The motor torque values applied by Exelon over-stressed this part, causing it to break and the discs to separate from the stem.

The NRC determined that the violation to be a Severity Level III Violation (out of a four-level system with Level I being most serious) based on the failure of the valves preventing the HPCS system from performing its safety function.

But the NRC exercised enforcement discretion per its Enforcement Policy and did not issue the violation. The NRC determined that the valve design defect was too subtle for Exelon to have reasonably foreseen and corrected before the Unit 2 valve’s failure.

UCS Perspective

Exelon looked pretty good in this event. The NRC’s SIT documented that Exelon was aware of the Part 21 reports made by the Tennessee Valley Authority and the valve’s vendor in 2013. That they were unable to use this awareness to identify and correct the problems with the Unit 2 HPCS injection valve is really not a poor reflection on their performance. After all, they performed the measures recommended by the Boiling Water Reactor Owners’ Group for the two Part 21 reports. The shortcoming was in that guidance, not in Exelon’s application of it.

The only blemish on Exelon’s handling of the matter was its weak justification for operating Unit 1 until its next scheduled refueling outage before checking whether its HPCS injection valve was damaged or broken. But the NRC’s SIT helped Exelon decide to hasten that plan with the result that Unit 1 was shut down in June 2017 to replace the susceptible Unit 1 valve.

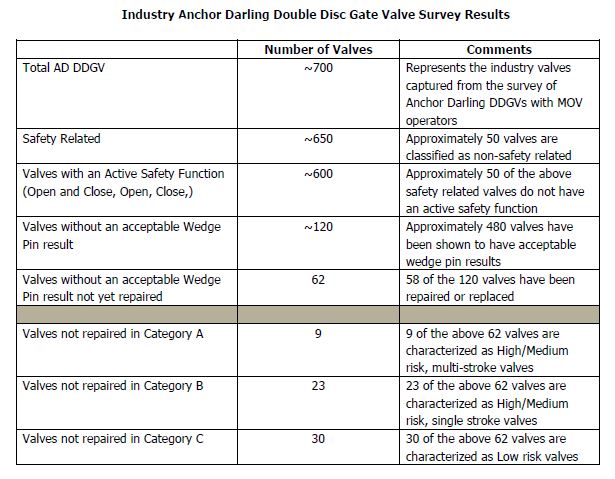

The NRC looked really good in this event. Not only did the NRC steer Exelon to a safer place regarding LaSalle Unit 1, but the NRC also prodded the entire industry to get this matter resolved without undue delay. The NRC issued Information Notice 2017-03 to plant owners on June 15, 2017, about the Anchor Darling double disc gate valve design defects and the limitations in the guidance for monitoring valve performance. The NRC conducted a series of public meetings with industry and valve vendor representatives regarding the problem and its solution. Among the outcomes from these interactions is a resolution plan by the industry enumerating a number of steps with target deadlines no later than December 31, 2017, and a survey of where Anchor Darling double disc gate valves are used in U.S. nuclear power plants. The survey revealed about 700 Anchor Darling double disc gate valves (AD DDGVs) used in U.S. nuclear power plants, but only 9 valves characterized as High/Medium risk, multi-stoke valves. (Many valves are single stroke in that their safety function is to close, if open, or open, if closed. Multi-stroke valves may be called open to open and close, perhaps several times, in fulfilling their safety function.)

Fig. 4 (Source: Nuclear Energy Institute)

There’s still time for the industry to snatch defeat from the jaws of victory, but the NRC seems poised to see this matter to a timely and effective outcome.