On Saturday night June 28, 1980, operators reduced power of the Unit 3 boiling water reactor at the Browns Ferry nuclear plant in Alabama. The unit was being shut down for a scheduled maintenance outage. At that time, procedures directed the operators to manually scram (shut down) the reactor when its power level dropped to about 30 percent. When that power level was reached, an operator depressed the two pushbuttons to cause the 185 control rods to insert into the reactor core within seconds. The operator observed that 76 control rods on one half of the core had not fully inserted. In fact, many of these control rods had hardly moved at all.

About two minutes later, the operator depressed the pushbuttons again. This time, 59 of the stubborn rods remained partially withdrawn. The operator depressed the scram pushbuttons a third time. There were still 47 control rods partially withdrawn.

The third time may be a charm, but it was the fourth time at Browns Ferry that night. When the operator depressed the scram pushbuttons a fourth time, all of the control rods were fully inserted. It had taken four tries and about 15 minutes to shut down the Browns Ferry Unit 3 reactor.

The control rods are moved into and withdrawn from the reactor core using hydraulic pistons. Control rods enter the reactor core of a boiling water reactor from below. To insert a control rod, water is applied to the lower side of the piston head and vented from its upper side. The differential pressure across the piston moves it, and the control rod attached to it, into the reactor core. Withdrawing a control rod involves the same process in the other direction: water is applied to the upper side of the piston head and vented from its lower side. Once again, differential pressure causes the control rod to move, this time out of the reactor core.

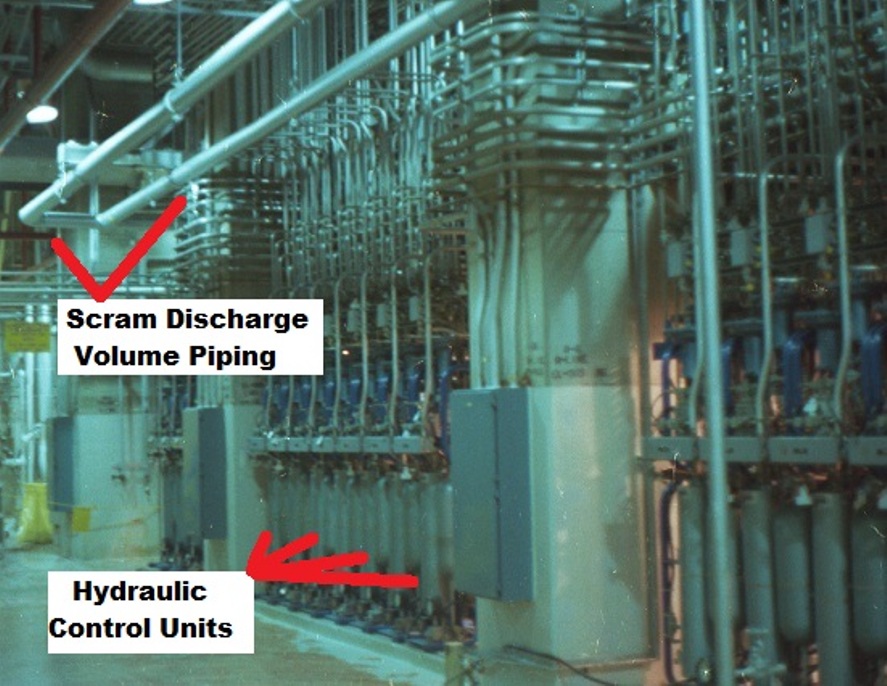

To maximize the differential pressure across the piston head during a scram, and thus achieve the fastest insertion rate of its control rod, the water above the piston head is emptied ino large pipes, labeled the “scram discharge volume” in the picture. Pressure at or above the pressure inside the reactor vessel is applied to the lower side of the piston head. This differential pressure drives the control rod fully into the reactor core in less than a handful of seconds.

No one ever determined conclusively what happened that night. The consensus is that something plugged one of the scram discharge headers. The fourth scram attempt supposedly dislodged this mystery plug and blew it into the reactor building’s sump where it hid amid considerable other gunk and grime already there.

This scenario is plausible. The areas above the piston heads for the control rods on each half of the reactor core are piped to separate scram discharge headers. These headers are four-inch diameter piping containing sufficient volume to contain the water vented from the control rods on that half of the core during a scram. At Browns Ferry, one-inch and two-inch diameter piping connected the areas above the pistons to the scram discharge headers. And one-inch and two-inch diameter piping also connected the scram discharge headers to the sump in the reactor building basement.

Engineers postulated that a mystery plug obstructed the flow of water from one of the scram discharge headers to the sump. The control rod insertions made to reduce the reactor’s power level to 30 percent partially filled the scram discharge header. When the first scram was initiated, the scram discharge header completely filled. As the pressure on both sides of the piston heads equalized, the control rods on that side of the core stopped moving.

Between scram attempts, some water leaked by the mystery plug. That explains why subsequent scrams saw some control rod insertions. Between the third and fourth attempts, the plug disappeared as mysteriously as it had appeared, allowing the header to drain. Thus, the fourth attempt was successful.

Computer output obtained between each scram attempt allowed analysts to conclusively demonstrate that while a portion of the reactor core remained critical after the first, second, and third scram attempts, considerable margins were maintained to fuel safety limits. The outcome might have been different had the reactor needed to shut down within seconds instead of within a quarter of an hour.

Our Takeaway

In the early 1970s, the Nuclear Regulatory Commission (then called the Atomic Energy Commission) developed the Reactor Safety Study, also called the Rasmussen Report after the person who led the study. The Reactor Safety Study was proclaimed to be a comprehensive assessment of nuclear power plant risks. The odds of blocked scram discharge volume piping interfering with a reactor shutdown was specified as being less than 10-7, or less than one event in 10,000,000 opportunities.

It was a very long shot at Browns Ferry that Saturday night in June 1980. Or, perhaps the Reactor Safety Study had been just a wee bit optimistic.

“Fission Stories” is a weekly feature by Dave Lochbaum. For more information on nuclear power safety, see the nuclear safety section of UCS’s website and our interactive map, the Nuclear Power Information Tracker.