Fission Stories #162

The control rods in boiling water reactors (BWRs) are withdrawn from the reactor core to initiate the nuclear chain reaction and to raise the reactor’s power level. Conversely, the control rods are inserted into the reactor core to reduce the power level and, when necessary, stop the nuclear chain reaction.

When withdrawn from the reactor core, control rods are located within metal cylinders called guide tubes directly below the core. Control rods are moved by supplying water to one side and discharging water from the opposite side. To withdraw a control rod, water is supplied to its upper surface and discharged from its lower surface. The reverse operation inserts a control rod: water is discharged from its upper surface and supplied to its lower surface.

Where Does the Water Come From?

To ensure it can rapidly insert into the reactor core during a rapid shutdown (scram), each control rod has its own accumulator (shown beneath the FROM label in the upper left of Fig. 1.) The accumulator is a metal tank partially filled with water. Nitrogen gas pressurized to over 1,200 pounds per square inch fills the rest of the accumulator. When the scram inlet valve opens, the pressurized water sends the water quickly to the lower surface of the control rod. As the accumulator water inventory and nitrogen pressure decrease, water from the reactor vessel (pressurized to over 1,000 pounds per square inch) flow to the lower surface area.

Where Does the Water Go To?

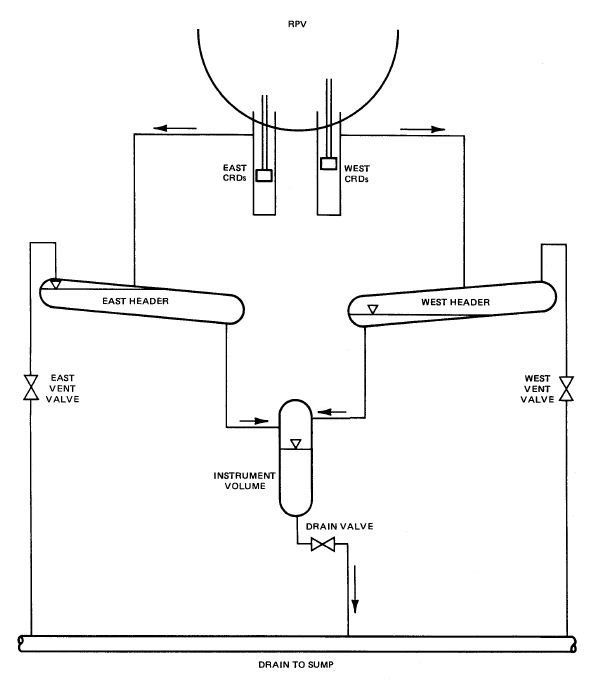

Fig. 2 shows the pathways followed by water discharged from the upper sides of control rods during their rapid insertion in a scram.

The water from roughly half of the control rods flows into the east header while the water from the other control rods flows into the west header. These headers are simply 4-inch to 6-inch diameter metal pipes. Water flows from the headers into the instrument volume. The instrument volume is a large metal cylinder sized to hold the water discharged from all control rods during a scram.

A pipe drains water from the instrument volume to the sump (a concrete pit) in the reactor building. Pipes also connect the east and west headers to the sump. The vent lines allow air to flow into the headers as they drain, preventing vapor lock from keeping the headers filled with water.

A scram signal opens the scram inlet and scram outlet valves. It also closes the vent valves on the headers and the drain valve from the instrument volume. Until the scram signal is reset and the scram outlet valves reclosed, the closed vent and drain valves prevent the water inside the reactor vessel from draining into the reactor building sump.

Steam Cleaning at Oyster Creek

On June 12, 1985, a turbine control system problem caused the automatic scram of the Oyster Creek nuclear plant in New Jersey from 99 percent power. The drain valve from the instrument volume to the reactor building sump was signaled to close, but failed to do so. With the drain valve open, hot water from the reactor vessel flowed into the reactor building sump. The atmospheric pressure in the sump allowed the hot water to flash to steam. The steam from the sump filled the lower two floors of the reactor building, triggering actuation of the fire sprinklers on the second floor about 20 minutes after the scram. Workers turned off the fire sprinklers in about five minutes.

The operators reset the scram signal 38 minutes after the reactor shutdown, reclosing the scram outlet valves to stop the flow of reactor water to the reactor building sump.

In addition to setting off the fire sprinklers, the steam contaminated the first floor of the reactor building by the radioactivity it contained.

Steam Cleaning at Dresden

On September 19, 1985, a different turbine control system problem caused the automatic scram of the Dresden Unit 3 reactor in Illinois from 83 percent power. Following the shutdown of the reactor, the operators reset the scram signal as directed by their procedures. But a mechanical problem with the reset switch caused the drain and vent valves to re-open but it did not re-close the scram inlet and outlet valves. For the next 23 minutes, hot water from the reactor vessel flowed through the open scram outlet valves and instrument volume drain valve to the reactor building sump.

As at Oyster Creek, some of the hot water flashed to steam upon entering the sump. The radioactivity in this steam contaminated the lower three floors of the reactor building.

Our Takeaway

These Oyster Creek and Dresden incidents illustrate the challenge faced by designers when safety interests compete.

Safety dictates that the system to shut down the reactor in an emergency be highly reliable. To meet this safety goal, designers placed the scram inlet and outlet valves, the headers and their vent valves, and the instrument volume and its drain valve in the reactor building instead of inside the primary containment building where it would be closer to the reactor vessel. The reactor building experiences a milder environment during an accident (e.g., lower temperature and pressure and less radioactivity) than exists inside the containment. Placing the components needs to scram the reactor outside containment increases their reliability in performing this safety function.

Safety dictates that water stay inside the reactor vessel and radioactivity stay within the containment building. To meet this safety goal, designers installed isolation devices to close off all but essential pathways to/from the reactor vessel and containment. The goal is to “bottle” them up to retain their contents.

Literally hundreds of 1-inch diameter pipes connect the reactor vessel inside containment to the scram components in the reactor building. Fig. 3 shows just some of those pipes passing through the containment wall at the Browns Ferry nuclear plant in Alabama.

If the drain valve fails, as happened at Oyster Creek or Dresden, or if one or more of these pipes break inside the reactor building, a pathway allows water to leave the reactor vessel and radioactivity to escape. Because all of the emergency systems that provide makeup water to the reactor vessel are located inside the reactor building, the pathway allowing water to leave the reactor could end up disabling the systems needed to replenish the water and cool the reactor core. If the reactor core gets damaged from overheating, the pathway provides the means for radioactivity to easily get through the several feet thick concrete containment walls.

Designers faced a safety trade-off: place the scram components inside containment at the price of reducing their reliability or place them inside the reactor building at the price of reducing the reliability of the reactor vessel and containment isolation capabilities. Time will tell if their calculus was right.

“Fission Stories” is a weekly feature by Dave Lochbaum. For more information on nuclear power safety, see the nuclear safety section of UCS’s website and our interactive map, the Nuclear Power Information Tracker.