The Oyster Creek Nuclear Generating Station near Forked River, New Jersey is the oldest nuclear power plant operating in the United States. It began operating in 1969 around the time Neil Armstrong and Buzz Aldrin were hiking the lunar landscape.

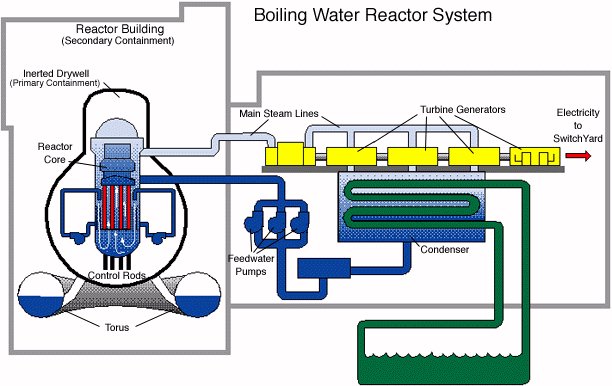

Oyster Creek has a boiling water reactor (BWR) with a Mark I containment design, similar to the Unit 1 reactor at Fukushima Daiichi. Water entering the reactor vessel is heated to the boiling point by the energy released by the nuclear chain reaction within the core (see Figure 1). The steam flows through pipes from the reactor vessel to the turbines. The steam spins the turbines connected to the generator that produces electricity distributed by the offsite power grid. Steam discharged from the turbines flows into the condenser where it is cooled by water drawn from the Atlantic Ocean, or Barnegat Bay. The steam vapor is converted back into liquid form. Condensate and feedwater pumps supply the water collected in the condenser to the reactor vessel to repeat the cycle.

Fig. 1 (Source: Tennessee Valley Authority)

The turbine is actually a set of four turbines—one high pressure turbine (HPT) and three low pressure turbines (LPTs). The steam passes through the high pressure turbine and then enters the moisture separators. The moisture separators remove any water droplets that may have formed during the steam’s passage through the high pressure turbine. The steam leaving the moisture separators then flows in parallel through the three low pressure turbines.

The control system for the turbine uses the speed of the turbine shaft (normally 1,800 revolutions per minute) and the pressure of the steam entering the turbine (typically around 940 pounds per square inch) to regulate the position of control valves (CVs) in the steam pipes to the high pressure turbine. If the turbine speed drops or the inlet pressure rises, the control system opens the control valves a bit to bring these parameters back to their desired values. Conversely, if the turbine speed increases or the inlet pressure drops, the control system signals the control valves to close a tad to restore the proper conditions. It has been said that the turbine is slave to the reactor—if the reactor power level increases or decreases, the turbine control system automatically repositions the control valves to correspond to the changed steam flow rate.

The inlet pressure is monitored by Pressure Transmitters (PT) that send signals to the Electro-Hydraulic Control (EHC) system. The EHC system derives its name from the fact that it uses electrical inputs (e.g, inlet pressure, turbine speed, desired speed, desired inlet pressure, etc.) to regulate the oil pressure in the hydraulic system that positions the valves.

Fig. 2 (Source: Nuclear Regulatory Commission)

Bad Vibrations

In the early morning hours of November 20, 2016, the operators at Oyster Creek were conducting the quarterly test of the turbine control system. With the reactor at 95 percent power, the operator depressed a test pushbutton at 3:26 am per the procedure. The plant’s response was unexpected. The positions of the control valves and bypass valves began opening and closing small amounts causing the reactor pressure to fluctuate. Workers in the turbine building notified the control room operators that the linkages to the valves were vibrating. The operators began reducing the reactor power level in an attempt to stop the vibrations and pressure fluctuations.

The reactor automatically shut down at 3:42 pm from 92 percent power on high neutron flux in the reactor. Workers later found the linkage for control valve #2 had broken due to the vibrations and the linkage for control valve #4 had vibrated loose. The linkages are “mechanical arms” that enable the turbine control system to reposition the valves. The broken and loosened linkages impaired the ability of the control system to properly reposition the valves.

These mechanical malfunctions prevented the EHC system from properly controlling reactor pressure during the test and subsequent power reduction. The pressure inside the reactor vessel increased. In a BWR, reactor pressure increases collapse and shrink steam bubbles. Displacing steam void spaces with water increases the reactor power level. When atoms split to release energy, they also release neutrons. The neutrons can interact with other atoms to causing them to split. Water is much better than steam bubbles at slower down the neutrons to the range where the neutrons best interact with atoms. Put another way, the steam bubbles permit high energy neutrons to speed away from the fuel and get captured by non-fuel parts within the reactor vessel while the water better confines the neutrons to the fuel region.

The EHC system’s problem allowed the pressure inside the reactor vessel to increase. The higher pressure collapsed steam bubbles, increasing the reactor power level. As the reactor power level increased, more neutrons scurried about as more and more atoms split. The neutron monitoring system detected the increasing inventory of neutrons and initiated the automatic shut down of the reactor to avoid excessive power and fuel damage.

Workers attributed the vibrations to a design flaw. A component in the EHC system is specifically designed to dampen vibrations in the tubing providing hydraulic fluid to the linkages governing valve positions. But under certain conditions, depressing the test pushbutton creates a pressure pulse on that component. Instead of dampening the pressure piles, the component reacts in a way that causes the hydraulic system pressure to oscillate, creating the vibrations that damaged the linkages.

The component and damaged linkages were replaced. In addition, the test procedure was revised to avoid performing that specific portion of the test when the reactor is operating. In the future, that part of the turbine valve test will be performed during an outage.

Vibrations Re-Visited

It was not the first time that Oyster Creek was shut down due to problems performing this test. It wasn’t even the first time this decade.

On December 14, 2013, operators conducted the quarterly test of the turbine control system at 95 percent power. They encountered unanticipated valve responses and reactor pressure changes during the test. The operators manually shut down the reactor as reactor pressure rose towards the automatic shut down setpoint.

Improper assembly of components in the EHC system and vibrations that caused them to come apart resulted in control valves #2 and #3 closing. Their closure increased the pressure within the reactor pressure, leading the operators to manually shut down the reactor before it automatically scrammed.

The faulty parts were replaced.

Bad Vibrations at a Good Time

If every test was always successful, there would be little value derived by the testing program.

Similarly, if every test was seldom successful, there would be little value from the testing program.

Tests that occasionally are unsuccessful have value.

First, they reveal things that need to be fixed

Second, they provide insights on the reliability of the items being tested. (I suppose tests that always fail also yield insights about reliability, so I should qualify this statement to say they provide useful and meaningful insights about reliability.)

Third, they occur during a test rather than when needed to prevent or mitigate an accident. Accidents may reveal more insights than those revealed by test failures. But the cost per insight is a better deal with test failures.