Last fall, I read something about the Department of Energy (DOE) partnering with the Palo Verde Nuclear Generating Station (PVNGS) on a digital instrumentation upgrade project. The topic interested me for two reasons.

First, I’d toured the Oak Ridge National Laboratory in October 2013 as part of the Society of Environmental Journalists’ annual conference. One of the presentations at the lab covered the Light Water Reactor (LWR) Sustainability project. This project includes research in materials aging mechanisms and development of processes intended to extend the operating lifetimes of the U.S. fleet of nuclear power reactors. Second, the aging analog instrumentation in nuclear plants meant that more conversions to digital instrumentation would be necessary.

I contacted Dwight Mims—the Senior Vice President, Nuclear at PVNGS—to explain how much I would appreciate the chance to visit the site and learn more about the DOE/PVNGS partnership project. Back in the early 1980s, Dwight had been my boss’s boss when we worked for the Tennessee Valley Authority at the Browns Ferry Nuclear Plant. As we discussed a potential visit, I expressed interest in also learning more about onsite spent fuel management and FLEX implementation. Dwight said they would like to talk to me about employee engagement efforts at the site and to show me the nearby Energy Education Center. We worked out the details and arranged for my all-day visit to PVNGS on May 11, 2016. Greg Cameron, a Section Leader in the Regulatory Affairs & Compliance group, communicated with me to get all the necessary security background information.

Background on Palo Verde Nuclear Generating Station

The Arizona Public Service Company built three two-loop pressurized water reactors designed by Combustion Engineering about fifty miles west of Phoenix, Arizona near Wintersburg. Arizona Public Service Company applied to the U.S. Nuclear Regulatory Commission (NRC) on May 25, 1976, for construction permits for the three reactors. The NRC issued operating licenses for Unit 1 on June 1, 1985, for Unit 2 on April 24, 1986, and for Unit 3 on November 25, 1987. Each reactor unit is capable of generating more than 1,300 megawatts of electricity.

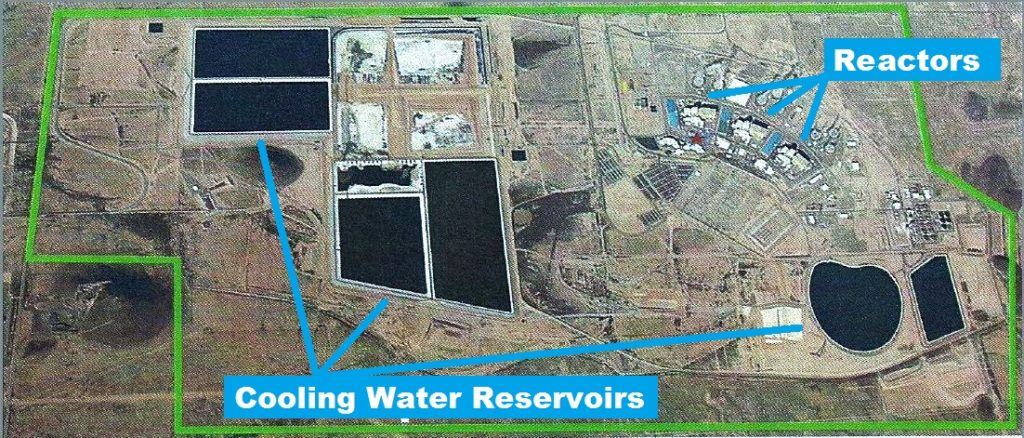

Fig. 1

The PVNGS has unique cooling water supplies. Other U.S. nuclear power plants are located next to oceans, rivers, and lakes. The PVNGS is located in a desert, and not next to a rare desert oasis. The plant gets water for everyday cooling needs from the city of Phoenix. For postulated accidents when this long distance supply might not be available, the PVNGS relies on water reservoirs (two per reactor) built onsite (Fig. 1).

Visit to the Palo Verde Nuclear Generating Station

I arrived at the Palo Verde site shortly before 6:45 am on May 11, 2016. Dwight met me at the security building and escorted me to a conference room in the administration building. Jack Cadogan, Vice President, Nuclear Engineering, led the introductions of the nearly two dozen PVNGS managers and staff in the room and then provided an overview of the site and its current status.

I followed with a short presentation on the Union of Concerned Scientists (UCS), our nuclear power safety mission, and current issues. Most of my remarks answered the title of my presentation, “What’s Right with this Picture?” by covering commendable outcomes achieved by the nuclear industry and the NRC.

FLEX Implementation

Gene Eimar, Shift Manager, Operations Support, and Mike Powell, Director, Fukushima Initiatives, discussed the measures undertaken at the PVNGS for the lessons learned from Fukushima. Their remarks focused on the FLEX equipment and its use, although they also touched upon some of the other measures taken.

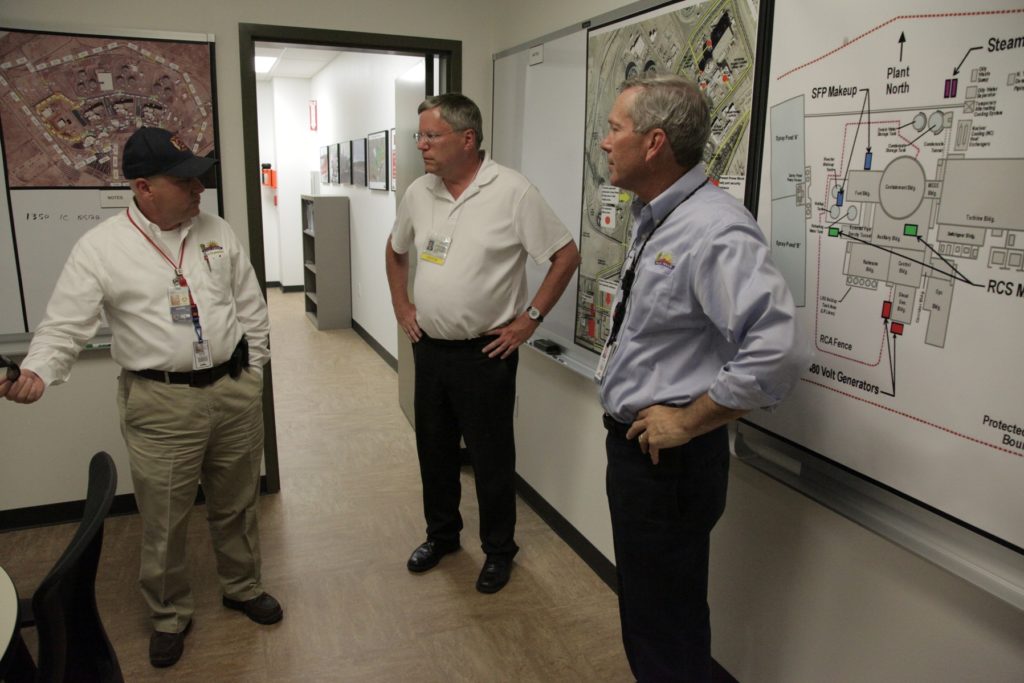

Fig. 2 Gene Eimar, Brian Blackmore, Dave Lochbaum, Don Vogt and Mike Powell.

Don Vogt, Acting Assistant Plant Manager for Unit 2, then led a three-plus hour tour of Unit 2 and the FLEX buildings. Gene Eimar and Mike Powell accompanied the tour to reinforce their presentation by showing where and how the FLEX equipment would be used. Brian Blackmore, Acting Director of Nuclear Engineering, also joined the group to cover the spent fuel pool and its cooling system (Fig. 2).

Fig. 3

Workers moved FLEX equipment from its storage building to pre-designated tie-down areas outside the auxiliary building (Fig. 3). The white metal rectangle in the center of the picture is a portable generator. Note the yellow straps connecting the generator to metal rings recessed in the concrete. Along with other straps not visible in the picture, the straps protect the generator from damage during an earthquake. The trailers on either side of the generator contain cables, hoses, and other FLEX equipment.

Fig. 4

I had concerns about the frequency and extent of training provided to workers responsible for these tasks. Gene showed how measures like color-coded cable and hose connections, in conjunction with periodic training, provide assurance that FLEX equipment can be relocated and hooked up in time (Fig. 4).

Fig. 5

The cables from the generator connect within a panel recently installed on the outside wall of the auxiliary building. After Gene showed me those connections, I asked why the generator was positioned so far away on its concrete pad. Gene explained that a primary extreme nature event at Palo Verde was a severe earthquake. The staging area for the FLEX generator was outside the falling debris zone. Workers would use fire trucks, front-end loaders, and other vehicles as necessary to clear a path for the cables from the generator to the connection panel (Fig. 5)

Fig. 6

Gene showed me where the portable hoses could be connected to piping to restore or replace the auxiliary feedwater (AFW) system (Fig. 6). The AFW system has a role similar to those played by the high pressure coolant injection and reactor core isolation cooling pumps at Fukushima. The AFW pumps are powered by steam produced by the reactor’s decay heat. FLEX enables portable pumps, power supplies, and water sources to perform the reactor core cooling function should the installed AFW system be unable to do so.

Fig. 7

The AFW pumps (blue casing in foreground) are among the most important safety systems in pressurized water reactors from a risk perspective (Fig. 7). The AFW pumps commonly fall into the top five safety components when ranked by risk.

Fig. 8

The emergency diesel generators (right background) are other safety components with high risk importance. While presumed to be disabled during a beyond design basis event, Gene and Don showed me the emergency diesel generators. They particularly called my attention to the air intake and exhaust ducts (Fig. 8).

Fig. 9

The FLEX building is relatively large and has more doors than I have seen at other nuclear plant sites. Mike McLaughlin, General Manager, Operations Support, and Kevin Foster, Department Leader, Fire Protection, explained that the building’s size enables them to run equipment in place for periodic tests. The multiple doors permit them to open doors for bays with running equipment to promote ventilation. And the multiple doors make it less likely that a jammed door or failed doors prevent FLEX equipment from being deployed in time (Fig. 9).

Fig. 10

The FLEX building includes rooms for staffing during an event and training before one. Kevin (left) and Mike (right) explained the periodic training conducted for plant workers and meetings held with offsite responders. Large maps and satellite pictures cover the room’s walls for use during the meetings (Fig. 10).

Fig. 11

En route to the FLEX building, our group visited the Unit 2 control room (Fig. 11). The reactor was operating at power, so Don Vogt asked for and received permission from the Shift Manager to walk me around the horseshoe panels showing me things.

Fig. 12

We also visited the training center. I learned that the PVNGS has two full-scale control room simulators, like the one behind Don and me (Fig. 12). Two control room simulators allow the company to stagger implementation of modifications to the three units across several years while minimizing the training consequences on control room operators. One simulator can model the reactor after an upgrade while the second simulator continues to model the reactors pre-upgrade.

PVNGS Organization and People

After the tour, we returned to the administration building for a working lunch. Randy Edington, Executive Vice President and Chief Nuclear Officer, talked about hiring and training practices at the PVNGS. Randy emphasized that the organization expects every worker to be focused on the mission of safely and efficiently generating electricity for the long term. I have read and heard similar mission statements many times over the years. Randy drilled past the slogan to reveal the programs and policies in place to enable and encourage workers to fulfill that mission.

For example, virtually every worker at the site including the security personnel, take a training course lasting several weeks on plant systems. (Another dividend from the investment in two control room simulators is being better positioned to have workers other than the individuals licensed as control room operators to benefit from the control room simulator experience.) Such practices represent investments in the work force; investments that lose value when workers quit to pursue different paths. But the investment seems to be paying off at the PVNGS—the worker retention rate five years after hiring is 90 to 95 percent.

Randy also presented data showing why the investment in people was especially important. The work force at the site is aging with a sizeable portion eligible for retirement in the next decade. Absent the investments in developing personnel, the departing workers will be a “brain drain,” With development policies including mentoring practices and training programs, the PVNGS will see new faces, but those faces will possess skills and professionalism comparable to the older faces.

Control Room Modernization

John Hernandez, Section Leader, Digital Modifications, provided information about the control room modernization project. John explained that the project involves more than just DOE and the PVNGS—the Electric Power Research Institute, Westinghouse Electric Corporation, and the Institute of Energy Technology Halden Reactor Project in Norway are all involved. The project’s goals are more ambitious than merely replacing analog gizmos with new-fangled digital equivalents. Three-dimensional modeling is being used to develop a virtual environment that can be tested in a human system simulation laboratory to design control panel layouts that maximize the human interface.

Fig. 13

The PVNGS has already acquired glasstop simulators. Don Vogt showed me one after he had referred to them several times and I did not know what he meant. A glasstop simulator is a trio of large computer screens that mimic a section of the control room panels (Fig. 13). The control room simulator in the picture features 14 glasstop simulators side-by-side in an L-shaped configuration. The glasstop simulator’s lower screen mimics the switches and knobs on an old-fashioned panel. Touch-screen capability allows the individual to replicate the actions taken when turning a switch or twisting a knob. The middle screen mimics the gauges, dials, indicators, and chart recorders of the old panels. And the upper screen mimics the alarm windows that alerted operators to off-normal conditions.

The control room modernization project will allow designers to do more than one-for-one replacements of obsolete analog components. It will enable them to re-position instrumentation and then “road-test” it in the virtual control room to see how effectively real people interact with the proposed configurations. An iterative process will allow refinements to hone in on the layout that provides the greatest benefit to the most users.

Onsite Spent Fuel Management

Brian Hansen, Department Leader, Nuclear Fuel Management, covered onsite spent fuel management. The PVNGS has the most robust spent fuel pool design that I have experienced. The spent fuel pools, the buildings housing them, and the systems that cool them are built to withstand a design basis earthquake. The cooling system for each spent fuel pool has two redundant trains, each train provided with power from offsite or emergency onsite sources. If cooling of a spent fuel pool is lost, backup supply is available from the Safety Injection System and from the FLEX portable pump and generator. The PVNGS loads about 6 to 12 dry casks each year to ensure that each spent fuel pool retains the capability of storing the entire reactor core should it become necessary to offload the core.

With three reactors, the PVNGS conducts at least one refueling outage every year. On top of annual refueling outages, the PVNGS loads at least 6 dry casks annually. Despite this sustained work load involving frequent handling of highly radioactive materials, there are only two pressurized water reactor plants with lower radiation exposures to workers than the PVNGS.

Employee Engagement

Michelle Gilchrist, Manager, INPO APOC, then led a discussion on employee engagement. Except for one other person and me, the people in the room for this session had not been on the tour or in the room during prior discussions. This group included representatives from the work control group, security, licensing, maintenance, and engineering. Nearly a dozen methods of engaging workers and enabling them to contribute their skills productively were described. For example, there are formal and informal mentoring programs as well as development initiatives. As I reviewed the list of methods on the PowerPoint slide to determine which was best, it dawned on me that having an array of options was far superior to any single method. Some people are introverted; others extroverted. Some people have aggressive personalities; others are passive. And so on. Even the best method appeals to a subset of the work force. The array of options allows every worker to find the method most suitable to him or her.

As employee after employee relayed his or her engagement narrative, it became obvious to me that they were not merely reciting slogans of the week or spouting messaging points. They provided concrete examples of how they used an engagement method in their work.

Another impression I formed during the employee engagement session was that they seemed more optimistic than management. This is not to suggest that management was pessimistic. Rather, I got the impression that management tempered their optimism with the realization of the challenges associated with ambitious goals. But it was repeatedly evident throughout the day that regardless of whether the work force or management was more optimistic, all worked as a team striving for the same goals.

West-MEC and the Energy Education Center

I left the site to drive a few miles to the Western Maricopa Education Center (West-MEC). The PVNGS is collaborating with city and county officials for a facility that includes areas for high school students. West-MEC already has classrooms with a water flow loop where students can complement book learnin’ with hands on experience. West-MEC also has an electronic laboratory with plans for additional program areas.

Across the street from West-MEC is the Energy Education Center (EEC). The EEC is part visitors’ center and part emergency response facility.

Fig. 14

Outside the EEC is a full-scale mock-up of a dry storage cask for spent fuel, cutaway to show its insides (Fig. 14). The question of how many Dave Lochbaums can fit into a dry storage cask remains rhetorical.

Fig. 15

Inside the visitors’ center of the EEC are several interesting displays, including a mock-up of the reactor core and one fuel assembly (Fig. 15).

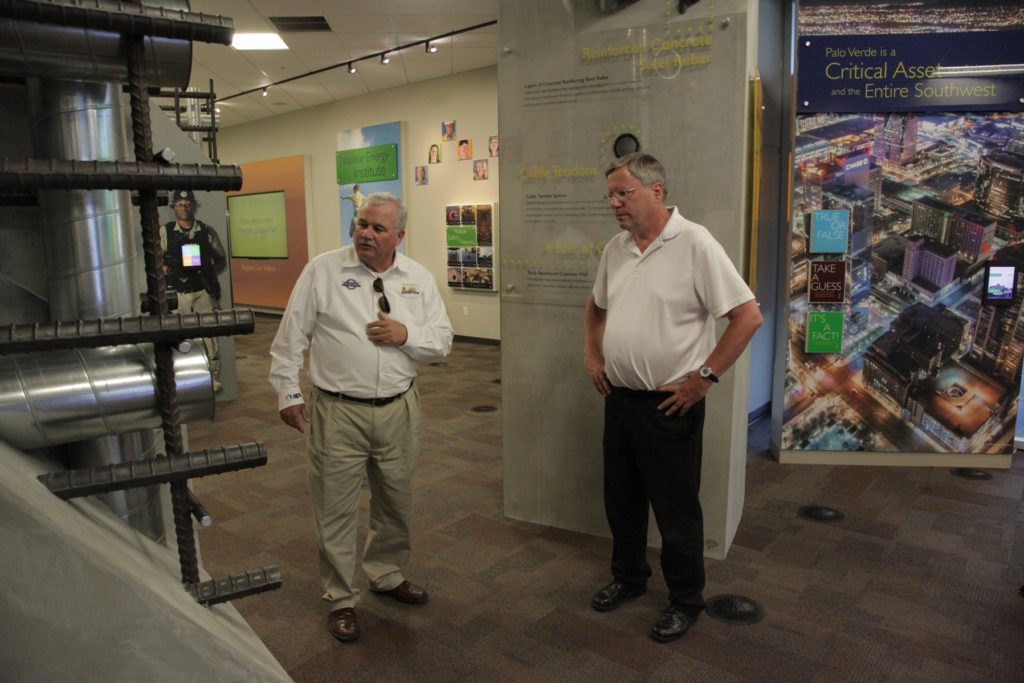

Fig. 16

Randy Edington guided me through the exhibits (Fig. 16). The EEC does a fine job of helping people visualize the plant’s features. Behind me is a display showing the thickness of the concrete containment wall. To Randy’s left, the display strips away the concrete to reveal the thick reinforcing bars (rebar) that add to the structural integrity of the wall.

The rest of the EEC contains facilities to be used in case of an accident. The Joint Information Center has a stage, podium, and theater seating for the news media. It also has smaller rooms for one-on-one interviews as well as areas for responders to monitor what is happening at the plant and its neighboring community.

Fig. 17

The visit to the PVNGS, West-MEC, and the EEC concluded around 6:30 pm, not quite 12 hours after it had begun. Randy Edington and his staff made my visit very high quality (Fig. 17).

Reflections on Palo Verde

First and foremost, I greatly appreciate the effort by the PVNGS staff in making my visit so productive and informative. Even if I could record the name of every person I met during the meetings and tours, I would be omitting the names of countless others who worked behind the scenes in support.

Many people throughout the visit told me about practices and upgrades at the site. They spoke with pride about these accomplishments. But I was surprised by how many people also referred back to darker times at Palo Verde. After years as a top performer, Palo Verde dropped into Column 3 of the NRC’s Action Matrix in the first quarter of 2005. Unit 3 dropped into Column 4 during the fourth quarter of 2006. The reactors did not return to Column 1 until the second quarter of 2009. At most sites, workers would not bring up such a saga and they would quickly dismiss it as ancient history if I mentioned it. But the memory is kept alive at the PVNGS as motivation. The site is justifiably proud of its successes; it is also aware of the consequences from failure. Complacency is an easy trap to fall into. While no one desires to be trapped, the PVNGS backs up its desire with vigilant awareness.

Key aspects of my job are context and corroboration. When presented with information, I strive to put it in proper context and find other information that either confirms or refutes it. I received lots of information during my visit to the PVNGS. As I processed it through my context and corroboration checks, it became clear that I was getting it straight without spin. Among many examples;

- I was told that the PVNGS had achieved its highest capacity factors ever. Other information I received showed that industrial accident rates and worker radiation exposure levels were at their all-time lows. The context—the PVNGS was not taking short-cuts and compromising worker safety in order to maximize production levels.

- The individuals during the employee engagement session spoke very positively about the support they received to do their jobs right. Corroboration—the high retention rate strongly suggests their attitudes represent the majority viewpoint rather than a cherry-picked minority perspective.

- Before the plant tour began, I was given the safety lecture including the reminder of using handrails when navigating staircases. Corroboration—Don Vogt quickly and courteously reminded me to use the handrail as we descended a staircase in the administration building hours later near the end of the tour after I’d taken a couple of steps without employing this safety measure.

- I was told that virtually all workers at the PVNGS attend a training class on systems lasting several weeks. Context and corroboration—several individuals relayed how they had used their acquired systems awareness to either solve or avoid safety problems.

The visits to West-MEC and the Energy Education Center were included at Dwight Mims’ suggestion. Both were impressive and well worth the time. The Energy Education Center is open by appointment only, but the PVNGS is eager to share its story with people. If you are in the area, you can arrange to visit the facility.

Famed basketball coach John Wooden’s defined luck as being when preparation meets opportunity. The hard work and dedication by the work force at the PVNGS focused on safely and efficiently generating electricity for the long term can achieve that goal through Wooden’s luck.

All photos from the Arizona Public Service Company