This blog was written in coordination with Ellie Peichel at Plug In America.

The number of electric vehicles (EVs) on our roads has been increasing at an exceptional rate, reaching 9.5 million EVs sold around the world in 2023. The EV transition offers many advantages, including the ability to reduce overall greenhouse gas emissions from the transportation sector.

At the end of an EV’s 10-15 year lifespan, the lithium-ion batteries powering the vehicle typically retain about 70-80 percent of their original capacity. At this point, there are several great options for the battery: it can be reused, repurposed, or recycled. Battery reuse includes using batteries in a similar application, placed directly in another vehicle, repurposing includes using batteries in a completely different application like stationary energy storage, and recycling is the process of recovering minerals to make new batteries.

Battery reuse and repurposing have huge environmental benefits because they reduce the need for manufacturing new batteries and extend the useful life of existing ones. Repurposing gets the most hype out of all the second-life solutions since it is an awesome option that uses old EV batteries to support a renewable grid. But let’s first talk about an option typically glossed over—EV battery refurbishing and reuse.

EV batteries can be refurbished and reused

Battery reuse occurs when refurbished battery packs are reused directly in another EV application, such as in a vehicle requiring shorter travel distances. Refurbishing batteries is similar to refurbishing other electronics – non-working parts are repaired/replaced to restore performance.

Over the last ten years, EV battery tech has significantly improved and this has resulted in EV battery range increases. Because of this development, refurbishment and reuse are becoming a more viable option. In 2023, the median EV range reached 270 miles for 2023 models. That’s almost 200 miles more than it was a decade ago, and future batteries will continue to improve!

As more EVs enter the market and older EVs reach the end of their useful life, there will be a resulting influx of used or retired battery systems that need to be processed. Battery refurbishing and reuse can be employed as tools to extend vehicle system lifetimes. This, in turn, can mitigate the need for new EVs and batteries, therefore also mitigating mineral usage and impacts.

…and repurposed for use in stationary storage!

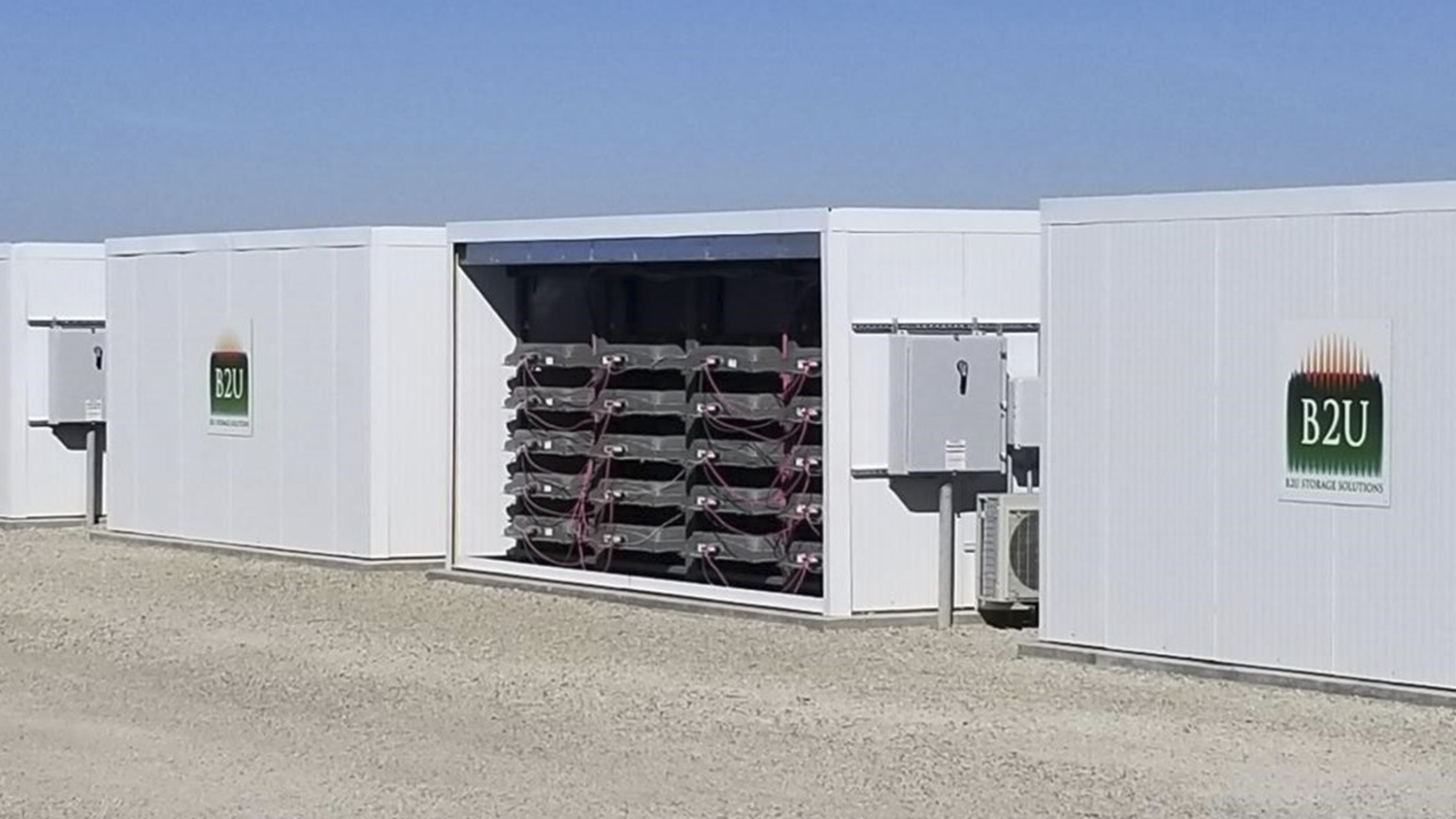

EV batteries can also be repurposed for different applications. As the electricity grid transitions to renewable energy, more stationary storage batteries are necessary to ensure electricity is available at all times. After a battery is used in an EV, it is removed from the car, and then tested several times to determine the health of the battery and if it is suitable for stationary storage use. If it is in good condition, the battery is connected with several others to create a larger battery system. Many of these systems are used to support solar arrays, such as the B2U system in the photo below.

A 25 MWh of storage capacity made up of 1,300 former EV batteries tied to a solar energy facility in Lancaster, California. CA Lithium-ion Battery Recycling Advisory Group report.

What are the barriers to reuse and repurposing?

Refurbished and repurposed batteries are competing with new batteries placed on the market, which have been dropping in price due to innovation. This innovation is great for the EV and stationary storage market, but because there are currently costly barriers to the second-life market, in some cases, it is cheaper to buy a new battery than a refurbished or repurposed one.

These costly barriers can be grouped into a few categories that follow the process of refurbishing and repurposing: transport, testing, and disassembly. Solutions to these barriers are given in the following section.

Additional costs of transportation: Once batteries are taken out of a vehicle, they are classified as hazardous waste and are therefore controlled by the rules that govern the transportation of hazardous wastes (which are often quite costly). There currently isn’t a separate waste classification for lithium-ion batteries, or a testing process to certify a used battery as safe for a second-life. Therefore we are not able to treat and ship these batteries similarly to a new battery entering the market. The EPA will be proposing new rules for waste designations to improve the management and recycling of batteries that may address this issue.

Difficult to disassemble: The EV battery is not designed to be disassembled, making it difficult to deconstruct. They also are not designed in a standardized way between makes, models, and even model years, therefore the process cannot be automated. Some repurposing companies forgo the disassembly process because of the time and cost associated and instead use the full battery pack, as seen in the photo above. Using the full pack may cut down on disassembly costs, but there are battery efficiency losses associated with not taking out bad cells, or grouping cells based on their capacity.

Lengthy testing process: To determine if a battery is suitable for reuse, it is important to know battery characteristics such as temperature, voltage, and capacity. Gathering this information was previously time and labor-intensive and required the full charging and discharging of a battery while being monitored. Startups are now developing tests that can determine these necessary data points in only a few minutes, drastically reducing time and associated costs.

Yes, all batteries should eventually be recycled

Eventually, all batteries should be recycled. Recovered minerals from recycling can be used in the manufacturing of next-generation EV batteries, offsetting the need for newly mined minerals. This is essential for reducing the environmental and social harms associated with mining and increasing the overall sustainability of EVs. While recycling is advantageous, it is important not to skip the reuse and repurposing steps. Research has shown that it is more environmentally beneficial to repurpose battery packs prior to recycling, even with the mineral efficiency of batteries increasing.

Policy solutions to increase reuse and repurposing

The US does not need to reinvent the wheel when it comes to policies that promote circularity in our battery supply chains. We can look to the European Union Battery Law for guidance on many policies that help facilitate battery reuse, refurbishing, repurposing, and finally, recycling. Below are some of these policies:

Extended producer responsibility (EPR): Extended producer responsibility makes the auto manufacturer responsible for ensuring that retired batteries are reused, repurposed, or recycled at the end of their life in an EV. When this requirement is placed on automakers, they are more likely to design the batteries and collection process in a way that increases efficiency and thus decreases the costs of end-of-life management.

Designing for disassembly: Disassembly of EV batteries is an important stage in reuse, repurposing, and recycling. As noted earlier, it is complicated by design variance, design complexity, and safety issues from varying end-of-life conditions. For example, inside individual EV battery modules, cells are usually glued or welded together. This makes it extremely difficult or impossible to replace dysfunctional cells on an individual basis. The solution lies in designing batteries in ways that make them easier and safer to disassemble later.

Battery labeling: Battery labeling is a crucial step in ensuring that all players along the battery supply chain have access to the information they need. Battery labels convey information about battery materials, chemistry, and design.

Digital battery identifier: A digital identifier for each battery can make data accessible that is necessary for reuse, repurposing, and recycling. This information includes battery state of health, battery chemistry, recycling content, and other key environmental and human rights information on batteries. The Global Battery Alliance is working with the EU to create a Battery Passport to fulfill the requirements of the EU Sustainable Batteries Law. The US could implement something similar to the Battery Passport to ensure sourcing transparency, support end-of-life processes, and track the overall lifecycle of batteries.

Let’s create a sustainable energy and transportation system

Promoting EV battery refurbishment, reuse, and repurposing in conjunction with recycling is paramount for the establishment of a sustainable and circular battery economy. By extending the lifespan of EV batteries through reuse and refurbishment, we significantly reduce the impact associated with battery production and disposal. Repurposing EV batteries for secondary applications beyond vehicular use maximizes their value and utility. These batteries, although no longer suitable for primary EV functions, still possess substantial energy storage capacity suitable for stationary storage systems.

By prolonging the life of EV batteries and providing second-life opportunities, we can decrease the impacts of battery production by reducing demand for new batteries. Regardless of whether batteries are reused, batteries will ultimately need to be recycled. Recycling can help mitigate impacts on communities along the battery value chain while strengthening the EV supply chain by increasing our domestic supply of energy transition minerals and reducing our need for primary materials extraction. By adopting these practices that promote a circular battery supply chain, we not only address pressing environmental challenges but also unlock new economic opportunities and pave the way for a sustainable and resilient energy future.