In the late 1960s, the Atomic Energy Commission (AEC), the forerunner of the NRC, paid the very companies that designed nuclear reactors—Westinghouse and General Electric (GE)—to test the efficacy of their own emergency cooling systems.

In the event of an accident in which a reactor loses water, uncovering the fuel rods—called a “loss-of-coolant accident”—these systems inject water back into the reactor in an attempt to prevent a meltdown. The tests that Westinghouse and GE performed were named the Full Length Emergency Cooling Heat Transfer (FLECHT) tests. The FLECHT tests simulated fuel rods undergoing a loss-of-coolant accident. The tests were intended to be as realistic as possible: bundles of 12-foot-tall rods, simulating fuel rods, were electrically heated up to reactor-accident temperatures and then inundated with cooling water.

Several of the tests were geared toward assessing how well the outer casing of fuel rods, called “cladding,” would endure in accident conditions. The cladding of fuel rods is primarily zirconium, a silver-colored metal. After the injection of water in an accident, hot-zirconium cladding is intended to endure the thermal shock of swift re-submergence and cooling. The cladding must not be stressed to its failure point. It is crucial that the fuel cladding perform well in an accident because it is a barrier preventing the release of highly radioactive materials into the exterior environment.

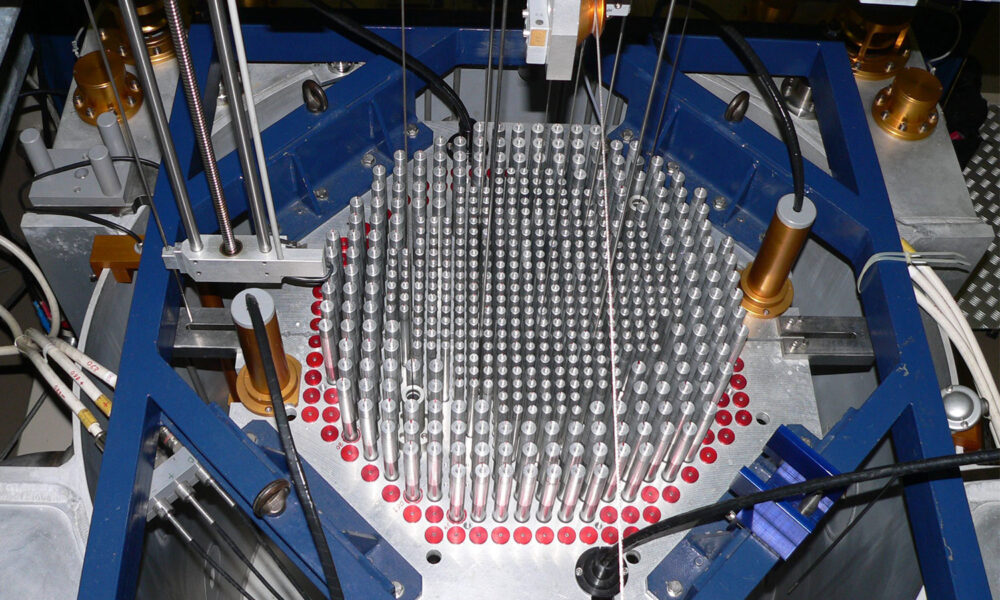

Figure 1. Source: Westinghouse)

Robert Leyse, my father, a nuclear engineer employed by Westinghouse, conducted a number of the FLECHT tests. On December 11, 1970, one of those tests, designated as Run 9573, had unexpected results. In Run 9573, a section of the test bundle’s zirconium cladding essentially caught on fire. The cladding burned in steam—then, when cooled, shattered like overheated glass doused with cold water.

Mr. Leyse instructed a lab assistant to take photographs of the destroyed test bundle, one of which is displayed as Figure 1. In a report on the FLECHT tests that Mr. Leyse coauthored, Westinghouse referred to the severely burnt, shattered section as the “severe damage zone” and noted that “the remainder of the [test] bundle was in excellent condition.”

Westinghouse’s FLECHT data is nearly 50 years old yet it is still highly regarded. The AEC used some of the FLECHT data to establish regulations that remain in place to this day. Westinghouse’s report on the FLECHT tests states that data from the first 18 seconds of Run 9573—before the cladding caught fire—is valid.

Concern over the extent zirconium burns in reactor accidents

In 2009, I submitted a rulemaking petition (PRM-50-93), requesting new regulations intended to improve public and plant worker safety. PRM-50-93 contends industry and NRC computer safety models under-predict the extent zirconium fuel cladding burns in steam. In more technical terms, the petition alleges models under-predict the rates at which zirconium chemically reacts with steam in a reactor accident. I buttressed my claims by citing data from FLECHT Run 9573 and other experiments conducted with bundles of zirconium cladding.

The zirconium-steam reaction produces zirconium dioxide, hydrogen, and heat. In a serious accident, the rate of the zirconium-steam reaction increases as local cladding temperatures increase within the reactor core. As the reaction speeds up, more and more heat is generated; in turn, the additional heat increases the rate of the reaction, potentially leading to thermal runaway and a meltdown.

It is problematic that the zirconium-steam reaction generates hundreds of kilograms of explosive hydrogen gas in a meltdown. In the Fukushima Daiichi accident—in which three reactors melted down—hydrogen leaked out of reactors’ containments and detonated, blowing apart reactor buildings. The release of radioactive material prompted the evacuation of tens of thousands of people and rendered a large area of land uninhabitable.

A “high priority”

In 2010, the NRC said its technical analysis of my 2009 rulemaking petition (PRM-50-93) was a “high priority.” Then, in 2011, the agency issued a press release announcing it intended to “increase transparency” in its petition review process by releasing preliminary evaluations of PRM-50-93. The announcement said the final decision on the petition would “not be issued until after the NRC Commissioners…considered all staff recommendations and evaluations.”

As part of the preliminary technical analysis of PRM-50-93, the NRC staff conducted computer simulations of FLECHT Run 9573. They compared the results of their simulations to data Westinghouse reported. However, there is a major problem with the staff’s simulations. They did not simulate the section of the test bundle that ignited. (Or if they did simulate that section, they decided not to release their findings.)

By way of an analogy: what the NRC staff did would be like simulating a forest fire and omitting trees reduced to ash and only simulating those that had been singed. After doing such a bogus simulation one might try to argue that trees actually do not burn down in forest fires. The staff basically did just that. They used the results of their simulations to argue that models of the zirconium-steam reaction are not flawed—that reaction rates are not under-predicted.

On January 31, 2013, I gave a presentation to the five commissioners who were heading the NRC at the time. They invited me to present my views in a meeting addressing public participation in the NRC’s rulemaking process. They apparently wanted my insights, because, in 2007, I raised a safety issue in a rulemaking petition (PRM-50-84) that they decided to incorporate into one of their regulations. I had pointed out that computer safety models neglected to simulate a phenomenon affecting the performance of fuel rods in a loss-of-coolant accident.

In my presentation, I criticized the staff’s computer simulations of FLECHT Run 9573. I said: “You cannot do legitimate computer simulations of an experiment that [caught on fire] by not actually modeling the section of the test bundle that [caught on fire].” In the Q and A session, Commissioner William Magwood assured me that he and the other commissioners would instruct the staff “to follow up on” my comments, including my criticism of the staff’s simulations of Run 9573. Then, five weeks after the meeting, Annette Vietti-Cook, Secretary of the Commission, instructed the staff to “consider and respond” to my comments on its review of PRM-50-93.

I hoped the staff would promptly conduct and report on legitimate computer simulations of FLECHT Run 9573. Instead, in March 2013, the staff restated that their prior, incomplete simulations of Run 9573 over-predicted the extent that zirconium burns in steam, indicating computer safety models are beyond adequate.

In November 2015, after I made a series of additional complaints, with help from Dave Lochbaum of the Union of Concerned Scientists, Aby Mohseni, Deputy Director of the NRC’s Division of Policy and Rulemaking, disclosed results of computer simulations of FLECHT Run 9573 including the section of the test bundle that ignited. The simulations drastically under-predict temperatures Westinghouse reported for that section.

The NRC’s severe-damage-zone computer simulations of Run 9573

The NRC’s severe-damage-zone computer simulations predicted cladding and steam temperatures for the FLECHT Run 9573 test bundle, at the 7-foot elevation, at 18 seconds into the experiment. (The severe damage zone was approximately 16 inches long, centered at the 7-foot elevation of the 12-foot-tall test bundle.)

The highest cladding temperature the severe-damage-zone simulations of Run 9573 predicted is 2,350°F, at the 7-foot elevation, at 18 seconds. Westinghouse reported that at 18.2 seconds into Run 9573, cladding temperatures by the 7-foot elevation exceeded 2,500°F. Cladding temperatures by the 7-foot elevation were not directly measured by thermocouples (temperature-measuring devices); however, Westinghouse reported that electrical heaters installed in the cladding began to fail at 18.2 seconds, by the 7-foot elevation, after local cladding temperatures reached higher than 2,500°F. Hence, even considering the time difference of a 0.2 second, one can infer that the severe-damage-zone simulations of Run 9573 under-predicted the cladding temperature by a margin of more than 100°F (at the section of the test bundle that ignited).

(Note that there is a time difference of a 0.2 second between the time the NRC picked for its simulations of Run 9573 and the time that the electrical heaters began to fail in the experiment. In the staff’s incomplete simulations of Run 9573—reported in the staff’s preliminary evaluations of PRM-50-93—the highest predicted cladding temperature is 2,417.5°F, at the 6-foot elevation, at 18 seconds. And the highest predicted cladding temperature increase rate is 29°F per second, at the 6-foot elevation, at 18 seconds. From these predictions we can infer that—although the value has not been reported—the highest predicted cladding temperature increase rate would be approximately 29°F per second or less, at the 7-foot elevation, at 18 seconds.)

In Run 9573, at the 7-foot elevation, the heat generated by the zirconium-steam reaction radiated to the local environment, heating the steam in proximity. The highest steam temperature the NRC’s severe-damage-zone simulations of Run 9573 predicted is 2,055°F, at the 7-foot elevation, at 18 seconds. Westinghouse reported that at 16 seconds into Run 9573, a steam-probe thermocouple mounted at the 7-foot elevation directly recorded steam temperatures that exceeded 2,500°F. And a Westinghouse memorandum (included as Appendix I of PRM-50-93) stated that after 12 seconds, the steam-probe thermocouple recorded “an extremely rapid rate of temperature rise (over 300°F/sec).” (Who knows how high the local steam temperatures actually were at 18 seconds; they were likely hundreds of degrees Fahrenheit higher than 2,500°F.) Hence, the severe-damage-zone simulations of Run 9573 under-predicted the steam temperature by a margin of more than 400°F (by the section of the test bundle that ignited).

The fact the NRC’s severe-damage-zone simulations under-predict cladding and steam temperatures that occurred in Run 9573 is powerful evidence indicating models under-predict the zirconium-steam reaction rates that occur in reactor accidents.

Qualifying power level increases for reactors

Since the 1970s, the NRC has approved more than 150 power level increases (termed “power uprates”) for reactors in the US fleet, enabling them to generate more and more electricity. An important part of qualifying a power uprate is to provide assurance with computer simulations that emergency systems would be able to prevent a meltdown if there were a loss-of-coolant accident at the proposed, higher power level.

A computer simulation is supposed to over-predict the severity of a potential nuclear accident. A margin of safety is established when a reactor’s power level is qualified by a “conservative” simulation—one that overcompensates. Meltdowns are less likely to occur if the reactor operates at a safe power level, providing a sufficient safety margin.

The extent zirconium burns at high temperatures has a major impact on the progression and outcome of a reactor accident. If zirconium-steam reaction rates are under-predicted by computer safety models, they will also under-predict the severity of potential reactor accidents. And, if power uprates have been qualified by models under-predicting the severity of potential accidents, it is likely power levels of reactors have been set too high and emergency cooling systems might not be able to prevent a meltdown in the event of a loss-of-coolant accident.

A petition review process of beyond eight years (with cherry-picking)

The NRC staff’s technical analysis of my 2009 rulemaking petition (PRM-50-93) was completed on March 18, 2016, but was not made publicly available until March 5, 2018, nearly two years later. The technical analysis signals an intention to deny PRM-50-93. It concludes with the statement: “Each of the petition’s key presumptions was investigated in detail. … The petition fails to provide any new information that supports a rule change. The NRC staff does not agree with the petition’s assertions, and concludes that revisions to [NRC regulations] or other related guidance are not necessary.”

Interestingly, a NRC staff e-mail, released in response to a Freedom of Information Act request, reveals that in August 2015—seven months before their technical analysis was completed—the staff already planned to deny PRM-50-93. At that time, the staff intended to announce their denial in August 2016.

The 2016 technical analysis of PRM-50-93 fails to discuss or even mention the results of the computer simulation of FLECHT Run 9573 that Mr. Mohseni disclosed in November 2015. Certain staff members appear intent on denying PRM-50-93 to the extent that they’re willing to make false statements and omit evidence lending support to the petition’s allegations. They appear determined to bury the fact their own computer simulation under–predicts, by a large margin, temperatures Westinghouse reported for the section of the Run 9573 test bundle that ignited.

The staff members who conducted the 2016 technical analysis of PRM-50-93 did not comply with the commissioners who directed them, in January 2013, to “consider and respond” to my criticisms of their simulation of Run 9573. The 2016 technical analysis has a section titled “Issues Raised at the Public Commission Meeting in January 2013;” however, that section fails to discuss the simulation results Mr. Mohseni disclosed in November 2015.

In April 2014, I submitted over 50 pages of comments alleging the staff’s preliminary evaluations of PRM-50-93 have numerous errors as well as misrepresentations of material I discussed to support my arguments. In my opinion, the 2016 technical analysis has the same shortcomings. I suspect that portions of the technical analysis have been conducted in bad faith. Perhaps certain staff members fear enacting the regulations I requested would force utilities to lower the power levels of reactors.

As a member of the public, who spent months writing PRM-50-93, I personally resent the way certain staff members disrespect science and efforts of the public to participate in the NRC’s rulemaking process. (The NRC gives lip service to encouraging public participation. Its website boasts that the agency is “committed to providing opportunities for the public to participate meaningfully in the NRC’s decision-making process.”) Even worse, much worse, their cynical actions undermine public safety.

In a written decision, D.C. Circuit appeals court judges said it was “nothing less than egregious” when a federal agency took longer than six years to review a rulemaking petition. The NRC has been reviewing PRM-50-93 for longer than eight years—procrastinating as well as cherry-picking.

UCS perspective

[What follows was written by Dave Lochbaum, Director of the Nuclear Safety Project at the Union of Concerned Scientists]

I (Dave Lochbaum) invited Mark Leyse to prepare this commentary. I more than monitored Mark’s efforts—I had several phone conversations with him about his research and its implications. I also reviewed and commented on several of his draft petitions and submissions.

Mark unselfishly devoted untold hours researching this safety issue and painstakingly crafting his petition. He did not express vague safety concerns in his petition. On the contrary, his concerns were described in excruciating detail with dozens of citations to source documents. (Reflective of that focused effort, Mark’s draft of this commentary contained 33 footnotes citing sources and page numbers, supporting his 2,300-plus words of text. I converted the footnotes to embedded links, losing chapter and verse in the process. Anyone wanting the specific page numbers can email me for them.)

Toward the end of his commentary, Mark expresses his personal resentment over the way the NRC handled his concerns. It is not my petition, but I also resent how the NRC handled, or mis-handled, Mark’s sincere safety concerns. He made very specific points that are solidly documented. The NRC refuted his concerns with vague, ill-supported claims. If Mark’s safety concerns are unfounded, the NRC must find a way to conclusively prove it. “Nuh-uh” is an unacceptable way to dismiss a nuclear safety concern.

In addition to handling Mark’s safety concerns shoddily from a technical standpoint, the NRC mistreated his concerns process-wise. Among other things, Mark asked the NRC staff to explain why it had not conducted a complete computer simulation of Westinghouse’s experiment, FLECHT Run 9573. The NRC refused to answer his questions, contending that its process did not allow it to release interim information to him. I protested to the NRC on Mark’s behalf, pointing out case after case where the NRC had routinely provided interim information about rulemaking petitions to plant owners. I asked why the NRC’s process treated members of the public one way and plant owners a completely different way. Their subterfuge exposed, the NRC “suddenly” found itself able to provide Mark with interim information, or at least selective portions of that information.

The NRC completed its technical analysis of Mark’s petition in March 2016 but withheld that information from him and the public for two years. The NRC would not withhold similar information from plant owners for two years. The NRC must play fair and stop being so cozy with the industry it sometimes regulates.

If how the NRC handled Mark’s petition is the agency at its best, we need a new agency. These antics are simply unacceptable.